With over 2,000 inhabitants, the title of seaside resort, miles of sandy beaches on the German Baltic Sea coast and a wildly eventful energy history with plenty of ups and downs behind and in front of it – Lubmin is not just an interesting place for friends of the Baltic Sea.

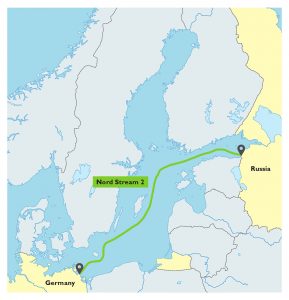

First of all, there is a decommissioned nuclear power plant here, which still provides a gigantic backdrop. Far less visible is the end point of the decommissioned pipelines from Russian natural gas fields, which seem very unlikely to be recommissioned. In view of climate change and the switch to renewable energies, the new LNG terminal will certainly not have a very long lifespan.

Windy prospects

In contrast, the connection to the wind farms in the Baltic Sea is completely different. Their energy is fed into the German grid here. The future of Lubmin is probably neither radiant nor gaseous. What was once the largest nuclear power plant in the German Democratic Republic is still being dismantled, a process that will take decades. Its nuclear waste, which will remain dangerous for thousands of years, will initially be stored in the Nord interim storage facility in the immediate vicinity. The steel pipes of Nord Stream 1 and 2 have no longer been transporting Russian gas since the invasion of Ukraine thanks to sanctions and sabotage. And the new liquefied natural gas terminal is also unlikely to have any long-term prospects if the energy transition and the phase-out of fossil fuels succeed.

Thomas Ehrhardt and Ehrenfried Wagner, on the other hand, are in the former fishing village and current seaside resort to work on the energy future of Lubmin and Germany’s adjacent electricity distribution grids. The two experts are part of the Energy Automation Team from Phoenix Contact in Gera. And they feel right at home in the large substation. “This is where the submarine cables of the two wind farms Baltic Eagle and Arcadis Ost 1 and feed the energy back into the German power grid,” says Thomas Ehrhardt, describing the situation on site. “In the past, the substation here was used to transform the electricity from the nuclear power plant into the grid. The 380 kV line from the Lubmin nuclear power plant ran to the Wolmirstedt substation in Saxony-Anhalt and, at 287.8 kilometers long, was the longest power line in Germany.” Ehrhardt points to the imposing plant in the background. “Today, this type of energy generation is history. But people use the facilities that were built here for this purpose. The port is also part of it, by the way, through which a good portion of the wind turbine generators were transported.”

Ehrenfried Wagner adds: “Offshore wind farms already have their own substations at sea, which collect the electricity from the individual wind turbines and transform it to transport-friendly 220 kV. These 220 kilovolts then arrive in Lubmin via submarine cable. Here the voltage is transformed to 380 kV. This voltage level is required for transportation over long distances.” The trained energy electrician for systems engineering explains the individual components as he walks through the extensive plant.

Peace on the net

We make a brief stop at one of the six huge transformers. “The former power grid of the GDR was based on the 220 kV voltage level, because dealing with 380 kV is much more complex. The grid operator 50Hertz is gradually dismantling all the old 220 kV systems and converting the entire grid to 380 kV. The advantages simply outweigh the disadvantages, especially the power loss in the lines is significantly lower.” He knows the substation like the back of his hand: “I worked here for the first time in 2008.”

The Energy Automation team from Gera looks after the grid operator 50Hertz, which maintains the eastern German power grid. “In addition to the standard maintenance and renewal of power grids, our normal day-to-day business, the extensive feed-in from offshore wind farms is what makes this special,” explains Thomas Ehrhardt. “Renewable generators such as wind turbine generators or solar power plants do not run as constantly as conventional large-scale power plants based on nuclear, gas or coal. The resulting fluctuations must be filtered out of the grids as far as possible. And our automation solutions switch, control, monitor and measure precisely these processes. They also have the necessary safety equipment to ensure that we can operate safely in the midst of this extremely high voltage in the open-air plant.”

Structure of the substation

Normally, the substation is remotely controlled directly from the 50Hertz headquarters in Berlin using remote control technology from Phoenix Contact. However, due to the extensive new construction and conversion work at the substation, the large site behind the nuclear power plant and interim storage facility is very busy these days. Ehrenfried Wagner points to two voluminous pieces of equipment: “These are the chokes, which are designed to filter out fluctuations in the grid and reduce reactive power. Capacitors absorb the current for a short time or release it again. Transformers, we also call them interconnected couplers, take on the active part in terms of power grid stability through unique voltage regulation. The power grids will continue to face ever greater challenges in the future as the output of renewables continues to increase. The effort required to keep the grids stable is also increasing. And more and more automation is required to compensate for the constantly changing fluctuations. Nobody can do this manually any more. And that’s what we’re here for.”

As we walk back to the substation’s control room, Wagner explains the various lines buzzing above our heads. “The 220 kV lines that are still here connect to the surrounding substations that have not yet been upgraded to 380 kV.” Inside the sober utility building, there is a hive of activity. “We plan and assemble the control cabinets we install here based on the grid operator’s requirements. And we then commission the systems here on site, i.e. we adapt the programming and coordinate it with the operator and the installation company here in Lubmin. And, of course, we also take care of servicing during operation.” Around 30 control cabinets are required per system.

Endurance technicians

While Energy Automation Phoenix Contact is based in Gera and looks after the eastern German power grids, Energy Automation, based in Velbert, is responsible for large areas of the old federal states with their grid operators. “Our job is a bit like a cycle,” smiles Thomas Ehrhardt, “we work our way from one end of the grid to the other and then start all over again. Power grids have to work around the clock every day, and so do our plants and systems. We work here in the critical infrastructure sector, where continuity and reliability are the watchwords. And we have made a very good name for ourselves in this area.” Not a business model for the fast euro or exponential growth, as the two heavy current experts explain. But it is indispensable for the dramatic changes that the energy revolution has in store.

Lubmin: There is hardly any other place in Germany – with the nuclear power plant behind it, the pipelines underfoot and wind power off the coast – where it is clear how central stable electricity grids are to the success of renewable energy sources and the vision of an all-electric society.