It’s cold up here. Icy cold. An almost unreal atmosphere lies over the Valle di Lei. In the background, Pizzo Stella rises in the Oberhalbsteiner Alps. The pressure of 200 million cubic meters of water lies on the enormous dam wall. A wall that connects. Switzerland on one side of the valley, Italy on the other. And in the middle of it all, an energy storage facility that provides electricity for 350,000 households.

The Swiss know their Alps inside out. In the case of the Hinterrhein power station, especially inside. In one of the largest plants of its kind, the Swiss have succeeded in harnessing the energy resources of Lake Lei all year round in three power plant groups thanks to sophisticated pump and generator technology and impressive tunnel systems. Around 45 percent of the 1,400 GWh of electricity generated here is used in the winter months.

The hydrological crank

The up to eight kilometer long reservoir that covers the Reno di Lei valley today was built between 1956 and 1963 and is located entirely on Italian territory, while the dam wall is on Swiss territory. A treaty between Italy and Switzerland made it possible to build the huge dam, which has a crown length of 635 meters. Between 1957 and 1963, 840,000 cubic meters of concrete were formed into a 138-meter-high arched wall, which has since stood up to the maximum 197 million cubic meters of water.

The Reno di Lei was formerly called the Lei Rhine and actually flows into the Rhine. This makes it the only body of water in Italy that ultimately flows into the North Sea.The lake is fed by melt water from winter snowfalls and rainfall during the rest of the year. Above all, however, Lago di Lei serves as a reservoir into which water is pumped up from smaller and lower reservoirs, some of which “collect” their water from other valleys. However, this is only done when the connected three turbine sites are not to generate electricity. If there is enough electricity, the excess energy is used to pump water into the reservoir, which is located almost 2,000 meters above sea level.

In the mountain

Change of scene: By car, the 950-meter tunnel takes us back to the canton of Graubünden. Through the Avers Valley, we head downhill to the headquarters in Avers, located almost 500 meters lower than the reservoir. Corsin Spiller is already waiting for us in front of the entrance to the plant. The 58-year-old is responsible for the electrical systems and ancillary facilities. In a staff function, he is also responsible for safety and the environment at the Hinterrhein power stations. He has been working here for 29 years, so he knows “his” plants inside out and, above all, inside out. After all, the great wall of Lago di Lei is not the only structure designed to turn water into electricity.

“There are a total of five dams here in different reservoir areas, connected by 59 kilometers of tunnels and shafts. With our total of three power stations, we achieve an average annual production of 1,368 gigawatt hours.” Corsin Spiller’s voice begins to echo as we walk down a 180-meter tunnel into the power station.

That’s right: Ferrera headquarters is located in the middle of the mountain. The gigantic machine hall opens up in front of us. Three Francis turbines find room in the 143-meter-long, 29-meter-wide and 24-meter-high cavern. These turbines can generate electricity as a turbine and pump water as an engine in reverse mode. “The light in here is controlled so that we have daytime-like conditions,” explains the electrical engineering graduate. “That makes it easier for the operators on the shift system here in the mountain. It’s a sophisticated control system that we developed ourselves here.”

There is even a real castle here. However, one in which probably only water sprites would feel really comfortable. This so-called surge chamber is a huge, circular hall. It is needed to compensate for and dampen pressure fluctuations in the pipelines of the hydroelectric power plant. The huge cavern could easily accommodate several apartment buildings.

Cutting instead of screwing

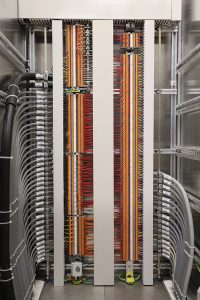

The next walk through the mountain leads to the areas where Phoenix Contact products are used – the switching devices. Control cabinet after control cabinet – and everywhere the concise logo from Blomberg. “For several years now, we have been fully relying on Quickon terminal blocks,” Corsin Spiller points to the opened cabinet, “At first, the old power stations in particular were naturally skeptical. Cables belong screwed into the terminals, they said. But I was convinced that the mechanism of these insulation displacement connectors is naturally less susceptible to interference and errors, especially during replacement. I was able to prevail with my assessment. Since 2007, we have been using Phoenix Contact’s Quickon insulation displacement connectors on a large scale. Our first project was an outdoor switchgear in Sils im Domleschg, which today belongs to the grid company Swissgrid. And we’ve never been disappointed there, so far we haven’t had a single disruption.”

The topic of refurbishment and modernization has accompanied the project manager for many years: “A transformer has a life expectancy of around 40 years, a turbine runner can also last 20 to 35 years – but the entire control system, including the computer control, naturally does not last 40 years. There have always been minor repairs and system adjustments. And now it was time to bring the entire system up to the current state of the art. Over the last ten years, we have invested around 300 million Swiss francs in this.”

First, the PCB-containing coating was completely removed from the pressure tunnels. The electrical systems of the power plant structure itself were also put to the test in order to optimize the power yield. For example, an efficiency gain of two to three percent can be achieved with a better turbine. “With an annual output of around 1.4 gigawatts, that makes a decent difference.”

Challenges of the future

Reliable availability is crucial for the Hinterrhein power stations. The company faces major challenges due to the increasing energy requirements, for example, from charging parks for e-mobility or the server farms of the Bitcoin washing plants. Spiller explains, “This is difficult for our grid. We haven’t had any problems with washing machines and water heating in the past, but a fast-charging station for a Tesla, for example, already presents us with challenges. For example, if you settle in a small village in the mountains, build a multi-family house there and want to set up charging facilities for it, then we’re obligated to bring that connected load right up to the front of the house.”

In terms of personnel, the omnipresent shortage of skilled workers is also causing headaches for the people of Graubünden, despite the exciting jobs in one of Europe’s most beautiful regions. “Power station workers have a strenuous and responsible job, even if thanks to automation, for example here in Ferrera, the days of round-the-clock shift work are a thing of the past.” Only during maintenance phases does bustling activity fill the underground facilities; otherwise, the machines in the mountain are monitored and controlled from the command center in Sils.

Water, workers and contracts

At the moment, however, it is the so-called “home case” that is worrying the power station operators. Corsin Spiller explains: “Anyone who wants to use hydropower in Switzerland needs a concession. In the next few decades, concessions for dozens of Swiss hydropower plants will expire. We will have to deal with this issue in 2042. Numerous technical and also legal clarifications must be carried out well in advance.”

The rights to use hydropower are in the hands of the cantons and municipalities. These rights have been ceded to the power station operators of Hinterrhein Kraftwerke AG for 80 years. In accordance with the Water Rights Act, the power stations revert to the local communities or cantons when the concession expires. The wet parts (dam, penstocks, turbines) are free of charge, the dry parts (generators, transformers, control systems), can be taken over at a “favorable” price. But can cantons and municipalities “do” hydropower and energy production and marketing? The meaningful look of Corsin Spiller suggests that there are definitely different opinions on this question.

Bad weather requests

What impact does climate change have on the Alpine storage reservoir? The power station operator’s expression becomes serious: “We have the paradoxical situation that in the European interconnected system we no longer only provide our stored energy in winter, when the renewable energy producers deliver less yield. In summer, when the French rivers no longer carry enough water to cool the nuclear power plants there and they then have to be throttled back, our reserves are also called up. So far, that’s only three to four weeks a year, but it’s increasing.

If you look at the mountains today, for example at the glacier in the Valle di Lei, until 40 years ago it reached almost to the edge of the valley. Today it has virtually disappeared. This year, too, we have about two to three meters less snow in the mountains. That can last for a year or two. But if it lasts longer, it becomes problematic. So we workers are hoping for high-precipitation summer months and long, snowy winters.”

Water is a precious commodity that also makes an important contribution to the energy mix – if it is available in sufficient quantities at the right place. And it is used cleverly. Like in the Valle di Lei, at the Great Wall.