They belong to Switzerland like watches, banks and the Alps – tunnels. Hardly any other country is as adept at the art of perforating its interior as the Swiss. But the stone tubes require constant care. And every now and then, the technical inner workings need to be brought up to date.

Der Lake Vierwaldstätter See is picturesquely located at the foot of the Alps in central Switzerland. 114 square kilometers

of lake surface nestle in part tightly against rugged rock faces and ensured since time immemorial that many places were better reached by ship or boat than on foot or by car.

This only changed when the inhabitants of the lovely landscape began not only to climb over their mountains, but also to tunnel under them. The tunnels needed for this were initially driven through the rock by pickaxe, but since the invention of dynamite by Alfred Nobel, they have been blasted. Nobel, in keeping with this story, founded a explosives factory in the village of Isleten in 1873. The explosive products were used primarily to blast the Gotthard railroad tunnel through the mountains overhanging it.

Isleten is located on the shore of Lake Uri, a part of the large Lake Lucerne. Already in the second half of the 19th century, the first tunnels and galleries were built here along the lakeshore to reach the small village of Bauen. Today, pedestrians, cyclists and motorized traffic share the carved stone tubes in harmony. The Weg der Schweiz, a hiking trail created to celebrate the 700th anniversary of the Confederates, also runs partly in these tunnels.

Hiking trails and flowing traffic meet every now and then along the shores of Lake Uri. But even the tunnels deserve a rejuvenation every now and then. Schiltegg, Harderband and Cholrüti tunnels: Twice just under 400 meters and once 800 meters in length were waiting for technological renewal.

New luminaires for old tunnels

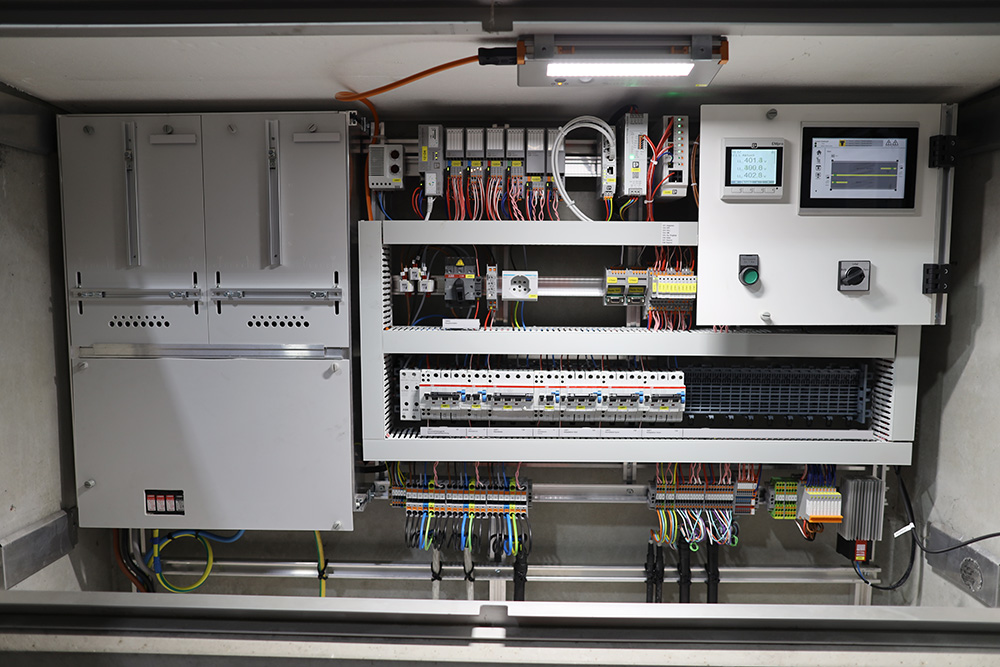

“The task was not only to renew the lighting with new LEDs, but also to replace their connections and the control system, including the contents of the control cabinets, and to put them into operation. And that was done in real record time,” recalls Jürg Uehlinger, System Engineer Energy Phoenix Contact and project manager for the control technology in this tunnel renovation. “We were only able to realize this with sophisticated preliminary work and thanks to our standardized control systems.”

“The schedule was very sporty,” confirms Marco Neuhaus, head of the executing company Silux AG, in conversation. “We were already involved in a preliminary project on this tunnel and already had contact with Phoenix Contact’s solutions then. However, our cooperation only became actual in mid-2020. In June, we received the financial release from the canton of Uri. Construction project planning and tenders then followed very quickly. The project was officially awarded in August. From then on, the implementation planning and the specifications had to be prepared and the material ordered. After all, everything should still be finished in 2020.”

Mounting with rock over head

Preliminary work such as new pavement markings dragged into the fall before electrical installations began in mid-November. “Tunnels are not a comfortable place to work during this time. It’s not only cold, but also drafty. After a while, you can’t feel your fingers or the wire that needs to be connected,” engineer Neuhaus knows from his own experience. “But fortunately there has only been a little rain.” Because the traffic routed through the construction site in a single lane lowers the feel-good factor even more thanks to transported spray.

“It’s not at all cozy in the tunnel in winter. When you have to wire cans there,

Marco Neuhaus, was active in the tunnels on site himself

you eventually can’t feel your fingers anymore.”

But the planned electrical installations went off like clockwork. “We were on site from December 1,” Jürg Uehlinger describes. “While we were still dismantling the old control cabinets on the first day, we were already able to put the first of the three tunnels back into operation on the second day. And after four days, we were completely finished.”

The final acceptance took place on December 7 without any problems. “We used PLCnext controllers that are matched with a standardized solution specifically for tunnel systems. This makes us extremely flexible and, above all, fast. We had almost no programming effort this way. The globally functioning standard, which we had already trimmed to Swiss standards and properties in other projects, thus only had to be minimally adapted to the project-specific requirements.”

Andreas Arnold, in the Baudirektion des Kantons Uri responsible for the tunnel renovation and thus the actual client, was visibly impressed: “From my side, it went very well. It was a great project, despite the tight schedule.” And Marco Neuhaus adds, “Thanks to the clever PLCnext controllers, it was even possible to change small details such as an additional switch without requiring any programming effort on our part. This modularity is exactly what we needed.”