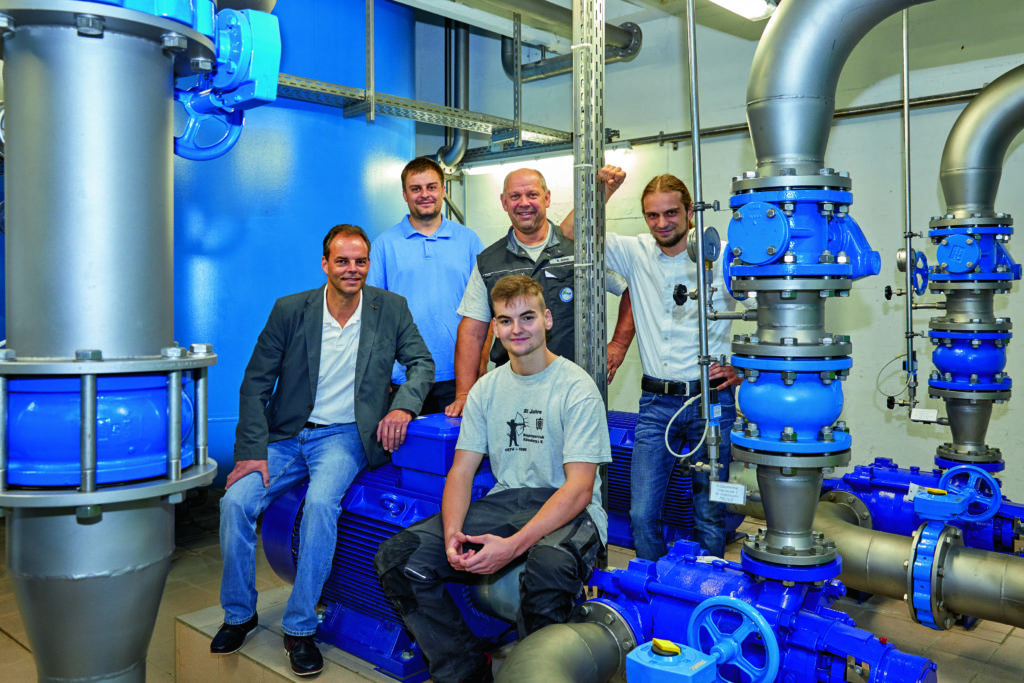

The Höchenschwanderberg water utility association in the southern Black Forest supplies around 24,000 inhabitants with drinking water from its three deep wells. The control technology needed to be modernized – using intelligent solutions and established technology

The effective control of pumps is the central task of the water supply facility in the southern Black Forest. This is hardly surprising, because in the region of Sankt Blasien and Höchenschwand through to the city of Waldshut-Tiengen there are two valleys with an altitude difference of some 360 meters to be negotiated. Many of the more than 18 elevated tanks have been in use for over six decades. The

pipeline network here alone covers around 65 kilometers.

In addition to topographical challenges, unfavorable weather conditions, heavy rainfall, and meltwater often also present challenges in maintaining high drinking water quality.

The water utility association is modernizing its systems in a continuous program staged over several years. Therefore, the water utility association places great value on systemic openness, as well as on the simple configuration of the visualization technology and efficient programming of the controllers. The association chairman, Mayor Stefan Dorfmeister, explains. “It should be possible for our employees to implement the operation and the upcoming system extensions themselves.” Furthermore, not only will the existing systems be modernized, but new visualization software will also be installed.

Flexible data feeds

Visu+ 2 from Phoenix Contact is therefore being used in the southern Black Forest. This is easy to connect to the controllers of different manufacturers, explains Dipl-Ing. Hans- Jürgen Fiene. The expert from Phoenix Contact explains, “Thanks to native communication drivers, controllers from different manufacturers can be connected efficiently and directly to the visualization software. This enables Visu+ 2 to access the data from the already installed S7-300 head-end station from Siemens without interrupting the data connection to the previously used visualization system.”

The complete engineering of the control system, comprising the visualization, analysis, and archiving of the data, signaling for the operating personnel, and the communication connection to the PLC head-end station, was taken over by the employees of Phoenix Contact Deutschland GmbH at the request of the utility association. The service includes setting up the PC system and installing it on site. All software solutions and the alarm portal are installed on an industrial PC system of the type BL RACKMOUNT 4U from Phoenix Contact.

Independent workers

Upon successful commissioning, the water specialists trained the employees of the utility association over a period of several days. This ensured the desired level of independence, because the maintenance and operating personnel are now able to realize optimizations efficiently and to keep the systems up to date with the latest technology.

A particular challenge is that the external structures – that is to say the pumping stations and elevated tanks – are to be controlled and monitored by the new control system. Since the utility association has its own cable network, albeit one which is more than 50 years old, Phoenix Contact is able to realize extensive IP networks through the use of Ethernet extender devices. Line lengths of up to 20 kilometers per path are possible with these. Thanks to the repeater function of the Ethernet extenders, even longer overall line lengths can be bridged. The data can be forwarded securely via the existing cable connections, because the data transmission signals are conditioned in each section of the path.

The water utility is using the ACX 1050 small-scale controller to integrate the field devices into the network. In the present configuration, this is fed with data from Danfoss frequency converters and Krohne electromagnetic water meters, among other sources. The field devices are connected via the Waterworx process library.

All data available at the control cabinet

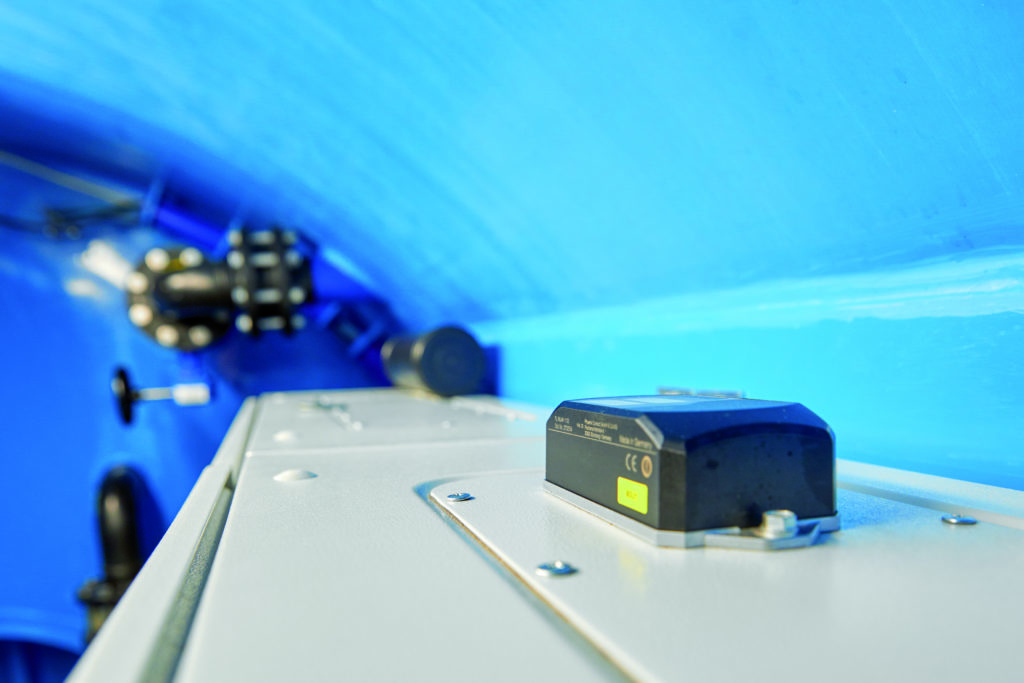

An additional requirement is that the employees are also to have an overview of the entire supply area even from the external facilities. They should be able to call up counter values and measured values, as well as adjust pump controllers, for example, by accessing the control system – without the need for someone to be at the main control center. This challenge is overcome with the WLAN 1100 access point, a complete WLAN solution that combines a wireless module with two antennas.

The employees can use this to connect to the control system via smartphone, tablet, or laptop. This means they can quickly identify and correct any errors that arise in the event of a malfunction.

A charming feature of the Black Forest water treatment plants: with the WLAN solution, the control cabinet does not need to be opened during the inspection. If an employee is within range of the WLAN point, he can call up the operating data.