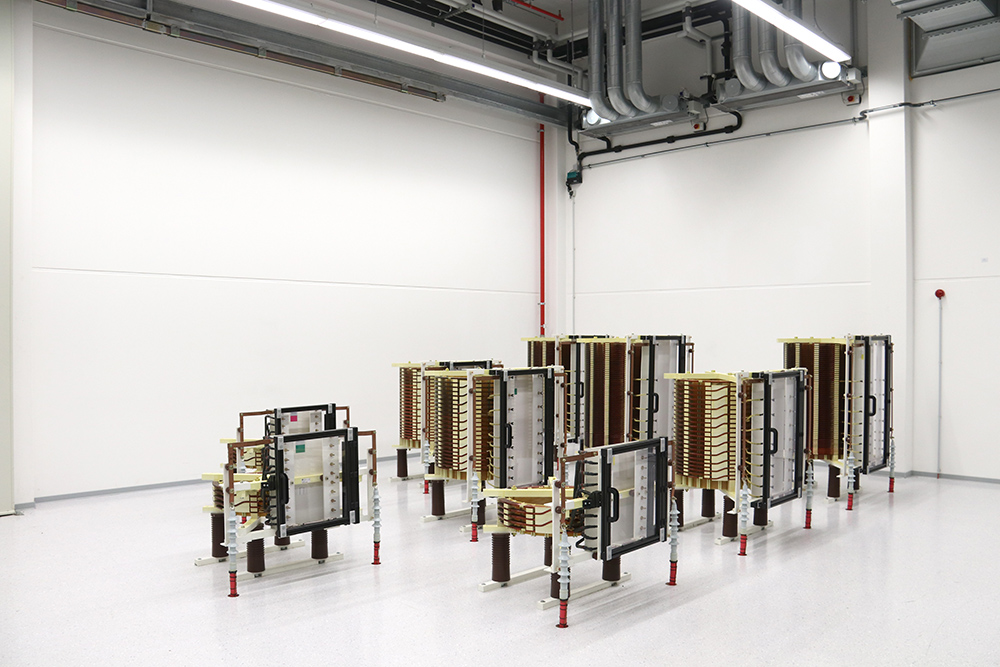

Sometimes it is the trivial things that draw attention to interesting details. If you walk through the Phoenix Contact high-current laboratory with alert eyes, the first thing you notice is of course the imposing test equipment. Coils, transformers and resistors in impressive numbers and, above all, enormous dimensions. Here, lightning can be simulated that reaches a strength of 100,000 amperes. The aim is to test surge protection elements developed in the System Protection Technologies business unit.

And at some point, perhaps shortly after spring cleaning your own four walls, when you visit again, you wonder why spiders, dust and voles seem to give this pearl of technology development from Phoenix Contact a wide berth. Are they afraid of the 30,000 volts that can be applied here?

Craft on a dangerous mission

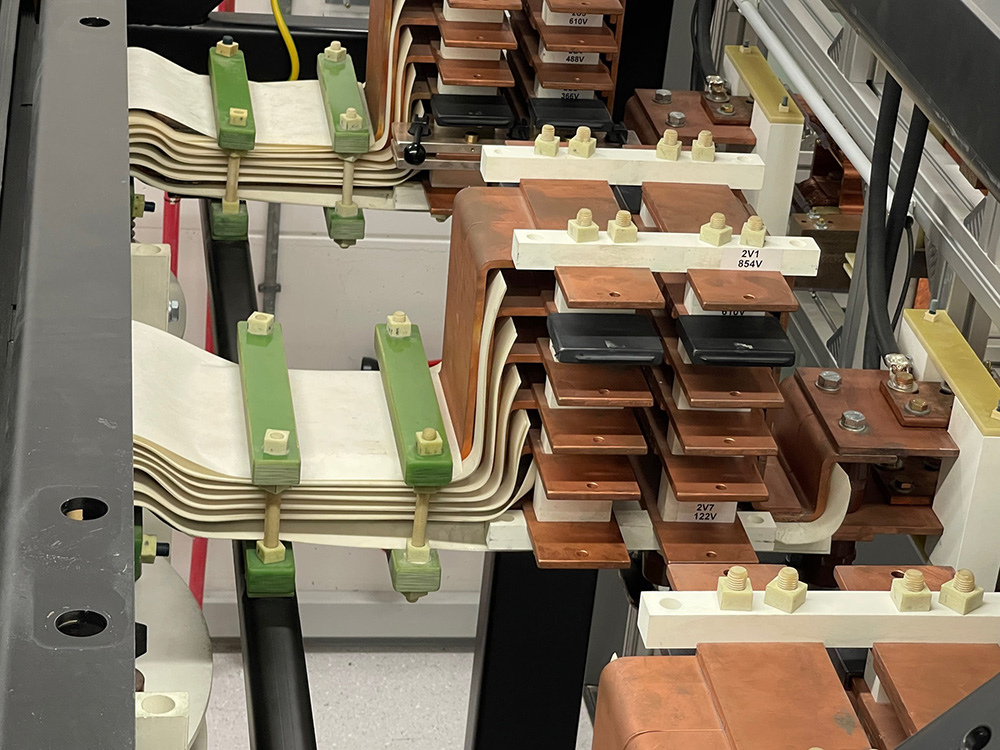

Frank Schäfer has to smile himself when he hears the question. But the issue is not quite so trivial. The deputy laboratory manager explains: “The classic cleaning squadrons are not allowed to enter the strictly protected area at all. Anyone who lends a hand here must know exactly what they are doing.” This requires trained personnel. Like Dirk Hoffmann from the Detmold company Elektro-Drücker. He actually arrives once a year, armed with a duster, cleaning cloth, special cleaner and plenty of expertise. The trained cable assembler and electrical installation specialist says, “I’ve been doing this here at Phoenix Contact for many years now and for a total of 35 years. It’s routine for us.” But how does one come up with the idea of this unusual niche in the competitive cleaning sector? The East Westphalian mumbles, “Among other things, our company specializes in cleaning large transformers and systems in the energy sector and industry. After all, they have to be kept clean.”

For good reason. The cleanliness is not for the sake of appearance or the supposed protection of spiders and co. Because in fact, dust deposits on the systems can lead to flashovers. And they discharge with a tremendous roar. “Then not only the equipment, but also the walls and ceiling are gone,” says Frank Schäfer, commenting dryly on the electrical forces at work.

But before the specially trained electrician tackles the dust, he makes sure himself that the plant is voltage-free, despite prior notification and special approval. “If that’s not the case and I’m careless, then in about 10 milliseconds I’d just be a pile of ash.” And Dirk Hoffmann doesn’t want to end up as dust, he wants to get rid of it. So everything grounded and short-circuited? Then it’s on to the dust bunnies.

He does his work with a cleaning cloth, a duster and a special cleaner, and gives tips along the way – with a twinkle in his eye. The cleaning cloth has to be white, he says. “Because otherwise it would stain. Then the beautiful white insulators would soon be pale pink.” And that would be funny, after all, because Phoenix Contact’s lightning current laboratory is a real visitor magnet thanks to its innovative technologies. Where dust bunnies and spider legs don’t stand a chance.

Elektro Drücker / Elektro Lampe

Mehr über die Herren der Blitze