They can trash. They can wheel hubs. They can power load. They can do trucks. And e-mobility on every scale anyway. Designwerk in Winterthur is one of the most exciting forges for new mobility in Switzerland and far beyond. A visit to the world of megawatts and heavy transport.

If you start at the beginning with the story of Designwerk, you begin with Tobias Wülser and Frank Loacker. The two tinkerers, one a model maker and designer, the other a machine builder, founded Designwerk in Winterthur in 2008. They hit the headlines when they circumnavigated the globe in 2010 in a self-built cabin motorcycle fully electric. And they did it so fast that they also pulverized the world record in this race around the world.

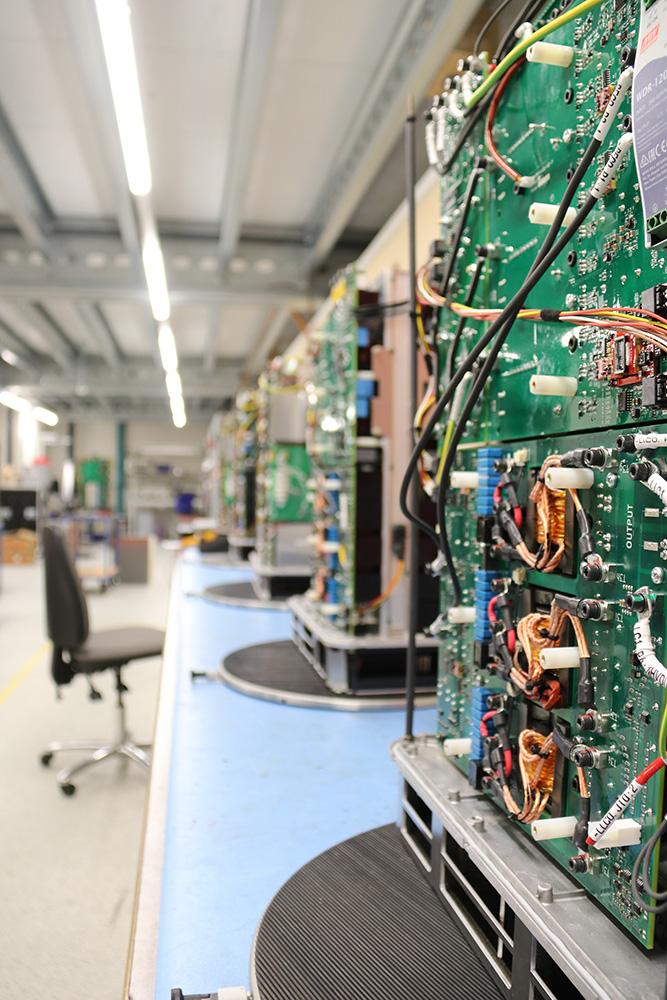

Since that time, Designwerk has been known in the e-mobility industry. And it has long since ceased to be just a hobbyist and extreme traveler, but also a service provider and producer of car and, increasingly, truck components for operating electrically powered vehicles. Under the former name Futuricum, the Winterthur-based company also entered into the production of its own trucks. This made fast charging of large traction batteries an important topic for Designwerk.

From concept to construct

Vivien Olivier Dettwiler is a mechanical engineer and has been with Designwerk for nine years. When he started, the start-up employed a whole 13 people. Since 2009, he has been part owner and appointed to the management of the company, which has now grown to more than 150 employees. “We started out as a pure service provider in the field of e-mobility,” he says, describing the tender beginnings. “Concepts, consulting, studies – that’s how we started. I joined as a development engineer for the first trucks, because we soon started to build up our own production.”

But the focus was initially on car technology. One commissioned project, for example, was the design of an electromobile successor to the 1950s classic BMW Isetta on behalf of a Swiss scooter manufacturer. And various products were developed in-house, such as mobile DC fast chargers for passenger cars. This was then joined by the company’s own battery production.

The chargers are used primarily by electric vehicle manufacturers throughout Europe. The third division is the reason for the visit, because trucks are actually produced here in Winterthur. The Swiss have virtually “grown into” this business model. “We started with the electrification, i.e. retrofitting, of conventionally powered vehicles. These were and are primarily municipal vehicles such as garbage trucks. And special vehicles, for example in the construction machinery sector,” says Olivier Dettwiler.

In 2015, the Winterthur-based company then unveiled its first “own” truck, a refuse collection vehicle. They have remained true to the color orange, and around 60 of the waste disposal vehicles are now in use in Switzerland alone. Initially, the designers limited themselves to vehicles for short distances, such as concrete mixers, refuse trucks with cranes and swap body systems. Heavy trucks, however, can be made mobile with conventional fast-charging technology thanks to short driving distances.

Particularly in special-purpose vehicle construction, electric drives are gaining an ever wider range of applications: emission-free construction machines for tunnels, for example, or vehicles for earth drilling, which are converting to electric buffer memories. Or manufacturers of plastering machines that electrify the drive unit. These machines are, of course, “hand-picked” in the truest sense of the word. Only the chassis, i.e. the basic body structure such as the frame, axles and wheels, is sourced from major manufacturers.

Customers with a hunger for range

For some years now, however, more and more logistics service providers have been approaching Designwerk. Vivien Olivier Dettwiler explains: “In Switzerland, we have a heavy vehicle fee, a ton kilometer fee. However, e-vehicles are exempt from this. And that explains the reason for the currently very high demand for alternatives to classic drives.”

There were chargers. There were batteries. There was experience in building trucks on bought-in chassis from Volvo and Mercedes. But initially there were no suitable trucks for the logistics specialists. So Designwerk began to use its know-how to build its own trucks. And send them out on the road under the name Futuricum. With these trucks, the Swiss entered new regions: “We started to look intensively at truck charging technology, because it’s quite different from car charging technology.”

Because, of course, the goal was clear from the start: “In Switzerland, as a small country, trucks don’t usually drive long distances. Until now, we only had trucks with a range of 200 to 300 kilometers. Then, a year ago, we started a project sponsored by the Swiss Federal Office of Energy (SFOE) to develop megawatt charging systems. Here, too, we have set new benchmarks.”

As at the beginning of the company’s history, the Swiss achieved a world record: In August 2021, a Designwerk truck covered a distance of 1,099 kilometers without intermediate charging. A 19-ton truck with over 680 hp and a capacity of 680 kilowatt hours, at the time the largest truck battery in Europe, was used.

Charging (almost) without limit

Not without pride in his voice, Dettwiler reports on the latest developments: “In the fall of 2021, we will have delivered the first two tractor units with 900-kWh batteries, with a range of 400 to 500 kilometers at a maximum possible charge of 40 tons. And this in combination with a charging system that recharges the batteries within around 100 minutes. In Switzerland, we can thus cover almost any distance. And that will then also make us competitive in the European market.”

In terms of charging technology, Designwerk has developed a broad portfolio, from the small AC charging inlet with 22 kW to the double parallel system with two AC vehicle charging sockets. In addition, there are fast charging solutions with 150 kW with a system voltage of 400 volts. If two battery blocks are optionally connected in series, Designwerk reaches 800 volts when charging.

“We then charge with a power of permanent 350 kW, at peak even 384 kW. We are the only ones who have managed this. There is currently no officially installed charging station in Switzerland that can deliver more than that for about two hours. By the way, the vehicle charging inlet from Phoenix Contact has no limit here; it works up to 600 amps.

In the area of charging stations and thus the establishment of the necessary infrastructure for logistics operations, we help if the customer wants us to. Alternative partnerships are often already in place, because there are quite a number of providers in Switzerland. But many have not understood the difference between trucks and cars. In most cases, the vehicle can be connected, but the charging times are not acceptable. Even nice marketing values are of no use here. That’s why we’ve started benchmarking charging stations. The problem of lack of power is not always the problem of the power infrastructure at the local level, but also often the continuous power capability of the charging columns.”

Megawatt – mega exciting

In the conventional CCS charging inlet, Designwerk wants to limit itself to 500 to 600 amps. But with the megawatt charging system, up to 3000 amps should be possible in the future. Dettwiler explains, “In reality, the truck is charged overnight. This gives the driver at least 640 kilometers of range in the morning. And during the day, with megawatt charging, he can recharge energy for another 450 kilometers in 45 minutes. This means that medium- and long-distance trips with 40-ton trucks can be realized at over 1000 kilometers per day. These are then ranges that cannot be extended even with diesel engines, if only because of the maximum driving times.”

In addition to the issue of charging technology with all its technological challenges, a look at costs is crucial, especially in the hotly contested industry of logistics. Here, too, the trucks from Winterthur can make up ground, as Dettwiler reveals: “An e-truck is around two to three times as expensive as a diesel vehicle. But in Switzerland, the business case with the heavy-duty charge pays off after three to four years, also due to the lower service costs. From then on, the higher investment already pays off.” It seems as if the next electromobile revolution is waiting in the wings …