He has been with Phoenix Contact since 2008, and Frank Possel-Dölken has been a member of the management board since August 2020. What has changed for the Chief Digital Officer since then? And what opportunities and risks does he see for the future of Phoenix Contact?

The year 2020 marked a turning point for Phoenix Contact. Because after many years of continuity, the management team of the Blomberg-based global market leader is changing. Professor Gunther Olesch left the company for reasons of age, Roland Bent (CTO) announced his departure in mid-2021. And no less than four new personalities have since strengthened the top management team. In a loose sequence, we introduce these “new” members of the management.

UPDATE: Mr. Possel-Dölken, you have been with Phoenix Contact since 2008. Tell us what professional stations you have completed before your task with us?

I studied mechanical engineering at RWTH Aachen University from 1994 to 1999, majoring in production engineering. I had the chance to go to Tsinghua University in Beijing for a year as a guest researcher before I did my doctorate back in Aachen. The topic was software development of control systems for machine tools in mechanical engineering.

UPDATE: So first a purely academic career?

Although I was also active in teaching, I have always been more of a practitioner who, among other things, was also active in business process management for many years. As a full-time scientist, I then worked in the Machine Tool Laboratory WZL. The WZL is very practice-oriented, so my first project was the development of a planning system for a flexible manufacturing system in the aircraft industry in Canada.

UPDATE: That sounds very exciting. Why then the change to the free economy?

It was. Most recently, I was managing director of the German Cluster of Excellence “Integrative Production Technology for High-Wage Countries. That was about production technology on a global scale, in which numerous partners from industry were also involved.

At some point, however, it was time for a change, because a scientific career was not really my thing, even though it was a nice time.

UPDATE: How did the contact with Phoenix Contact come about?

Of course, I already knew Phoenix Contact as one of the leading players in automation technology. Phoenix Contact was one of the pioneers when it came to the topic of wireless in industry. Phoenix Contact was also one of the first to create an environment for programming control systems with high-level languages when it came to IT-powered automation. We have molded this into PLCnext in such a way that it is really fun today.

UPDATE: So dream destination East Westphalia?

(laughs) Well. In 2007, at a mechanical engineering congress in Berlin, Mr. Hasse persuaded me over coffee to drop by Blomberg after all. The East Westphalia region was not at the top of my list of destinations, I’ll be honest. But I’m a Westphalian by family background, I can play Doppelkopf and I also go down to the cellar to laugh (broad smile). When my wife sat with me in a café in Detmold on a gloomy November day and said she could imagine a life here, the matter was decided. I then started in 2008.

UPDATE: But you didn’t start in automation development?

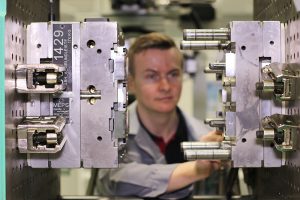

Right. I spent the first few years in the internal machine and tool construction department. This job gave me the opportunity to work on a wide range of topics with many colleagues in different areas of the company, which gave me a good overview. Equipment manufacturing may not sound very sexy, but at Phoenix Contact it is a real high-tech forge.

For example, I was there at the beginnings of the zinc die casting production, which is now located in Paderborn. At that time, this was a long-cherished wish of Klaus Eisert: A real connection technology company must have its own foundry. In addition, we started working on automation in switchgear construction at that time.

UPDATE: But that wasn’t all, otherwise we wouldn’t be doing this interview.

With the topic of product lifecycle management came a new task. I thus slipped into the area of Corporate Technology. In the end, I became head of Corporate Technology and Value Chain. This was followed by IT topics relating to product data and topics such as store floor management. That led to unit management from 2016 to 2019.

And then the gentlemen of the management approached me. Since August 2020, I have been a member of the management team myself.

UPDATE: What has changed for you?

Actually, not that much, because it was a smooth transition. But I have also worked in the past rarely more than two years without changes.

Of course, something has changed in the way we deal with each other. People are suddenly talking to me as one of the managing directors, I can tell. In this role, you have to think three times about what you say. People listen much more carefully and interpret three times more into what I say. That’s a change, of course.

UPDATE: Which areas are new in your responsibility?

I am responsible for the Digital Process and Solutions unit. This is a new organization that has been set up as a central function in the area of business process management. Our IT is part of it, plus the area of digital customer interaction from the e-shop to online marketing.

In addition, there are central tasks in the area of standardization. For example, I am involved in the national Industry 4.0 platform, where I represent the interests of Phoenix Contact. With the departure of the current CTO Roland Bent, I will be taking over our IP Management team from March of this year.

UPDATE:How do you get all these tasks into your schedule?

The time load has always been high. But sometimes this function is also about clearing your head to think things through. There has to be time for that. It’s not about meeting as many deadlines as possible or working through all the files. You can only lead if you don’t do everything yourself, but are also able to delegate sensibly.

Travel will certainly become more important in the post-Corona era. I have been to our sites regularly, especially in the USA and China. But in the future, I will have more frequent appointments that are not directly related to our production at the sites.

UPDATE: What are your upcoming tasks of the future? What do you find exciting?

Of course, I’m interested in topics like digital transformation and the associated internal process and IT infrastructure, digital products and services. That’s what I’m passionate about.

UPDATE: What are the challenges of the future for Phoenix Contact?

When I look back over the last few years, I see incredible opportunities in so many areas. The biggest challenge, therefore, is actually to decide what NOT to do.

This is a beautiful, but also difficult task. Because our activities are widely scattered. There are technology upheavals ahead, for example in e-mobility or regenerative energies. If you think alone that we are represented everywhere with our products, systems and control cabinets in the booming markets of wind and solar, then these are not exactly dark clouds on the entrepreneurial horizon.

The task in management is not to open up every market we could. Although it is tempting and the prospects are almost endless. Because that would simply overtax our forces, those of our 17,600 employees. For us, it’s not a question of closing sites or cutting staff. Our pain will be having to say no sometimes. No matter how fantastic the prospect.

To some extent, this is reflected in my personal area of responsibility. We do hold a lot of resources. But if we were to tackle all the highly interesting topics at once, we would also sink. Deciding what not to do is also my own personal new challenge.

UPDATE: What role will Phoenix Contact play against the backdrop of the All Electric Society theme?

In the end, with the size of company we have today, we also have to take on a social role. This is also a first step in focusing. If we are faced with the choice of becoming involved in industries that are tending toward the end of their life cycle or in future fields such as renewable energy generation or the hydrogen economy, then we will focus on the sustainable issues in the future.

Our products play an important role as technical enablers in many fields of application and industries. Against the backdrop of the All Electric Society, we will focus our development work in the future on areas where there is a direct link to important sustainability goals.

UPDATE: How do we proceed in markets that opt for fossil energies or nuclear power? Are we actually foregoing sales?

Nuclear power is very important in China or France, for example, and the oil and gas industry in the USA. But things are changing there, too. Sustainability, for example, is a high priority in the upcoming five-year plan in China. Likewise, large companies in the oil and gas business have started to adapt to the change and are trying to develop new business areas.

If we look into the circle of Phoenix Contact’s global executives, i.e. the circle of those responsible in the respective countries, then we naturally have people there who are attracted by Phoenix Contact’s way of thinking, i.e. who represent rather progressive attitudes. This enthusiasm is part of our entrepreneurial DNA.

And yes, we will also forgo sales in case of doubt.