Josef Ecker’s family has lived in Landshut in Lower Bavaria for generations. But the harvest that the gnarled scion of a farming dynasty reaps today needs no combine harvester, no pesticides and no fertilizer …

Josef Ecker is now a well-known face on the renewable energy generation scene. Anyone who has the pleasure of visiting the enterprising entrepreneur at his company headquarters near Landshut is first greeted by a Franconian idyll. In the middle of cornfields lies what at first glance appears to be a typical farmhouse. Lots of wood, an elongated main house, barns, agricultural machinery. Solar panels sparkle on the roofs – everyday life in the countryside.

Farmer wants … electricity

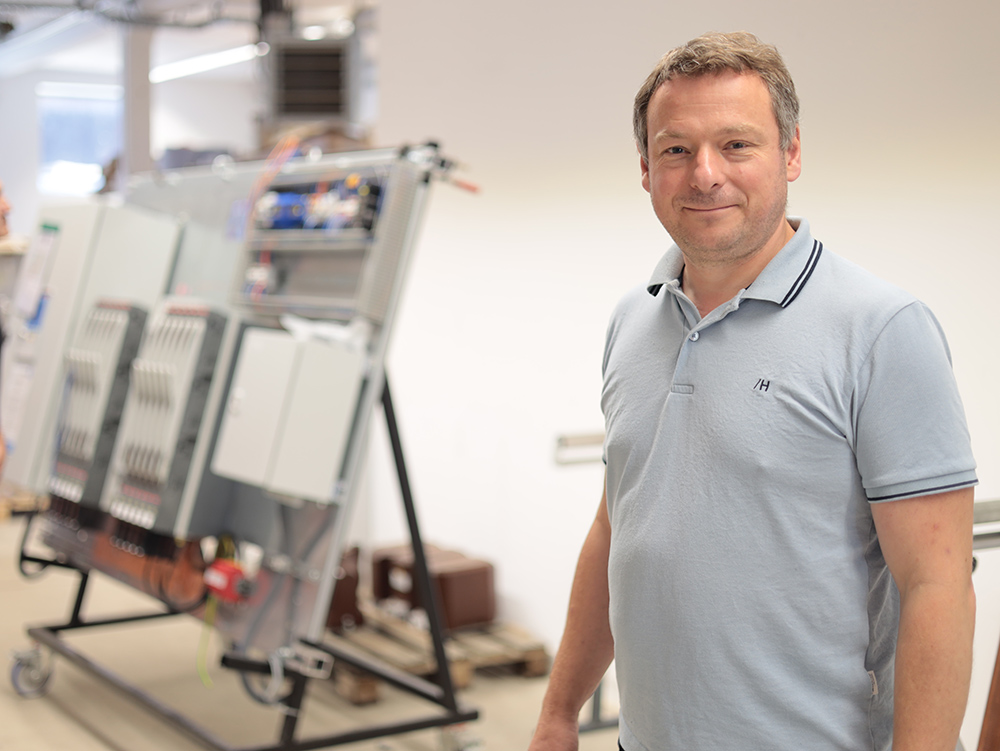

But anyone turning into the farmyard will be greeted by the energy transition. Dozens of heavy transformers are waiting to be installed in their matching secondary substations, and behind the open barn doors, large switching devices are waiting to be prepared for use. Josef Ecker and his team plan, develop, install and operate solar parks far beyond the borders of Bavaria.

“A bit of farming, a bit of electrician – that will be enough for life” – Josef Eckert has to smile himself when he talks about the beginnings of his business. “But now I don’t have time for farming anymore.” In 2008, the busy farmer’s son started his “sideline” electrical business. “In the beginning, it was a one-man show, together with a few students. And right from the start, it was exclusively in the solar sector. But I’m not an ecologist at all,” laughs Josef Eckert. “I trained as a farmer and an electrician, both of which are fully-fledged apprenticeships. At the time, the real motivation to switch to an electrical business was the lack of prospects in agriculture. We gave up the dairy farm in 1990 and the last animals left the farm in 1998. But the symbiosis of agriculture and photovoltaics was ideal, because we had large buildings and suitable areas that we needed to install the systems. I had the connection and spoke the language of agriculture. Even today, around 50 percent of our customers are farmers.”

Josef Ecker now employs a good 60 people who take care of the planning, construction and operation of solar parks, “from small to large”. Ecker is mainly active in Bavaria (“where people speak and understand our language”). The company is also its own customer, as Ecker also operates its own solar parks. However, the main focus is on building solar parks for customers. These are no longer just from the agricultural sector: “Today, tradespeople are also a major target group, as they want to get away from high electricity prices.”

Upon my soul!

But Josef Ecker and his team have long been known far beyond the borders of their beloved Free State. And that has to do with their typical Bavarian stubbornness. “And with our thriftiness,” adds Helmut Schratzenstaller with a grin. The trained electrician has delved deep into the world of IT and control systems and is now one of the experts when it comes to programming Ecker’s systems.

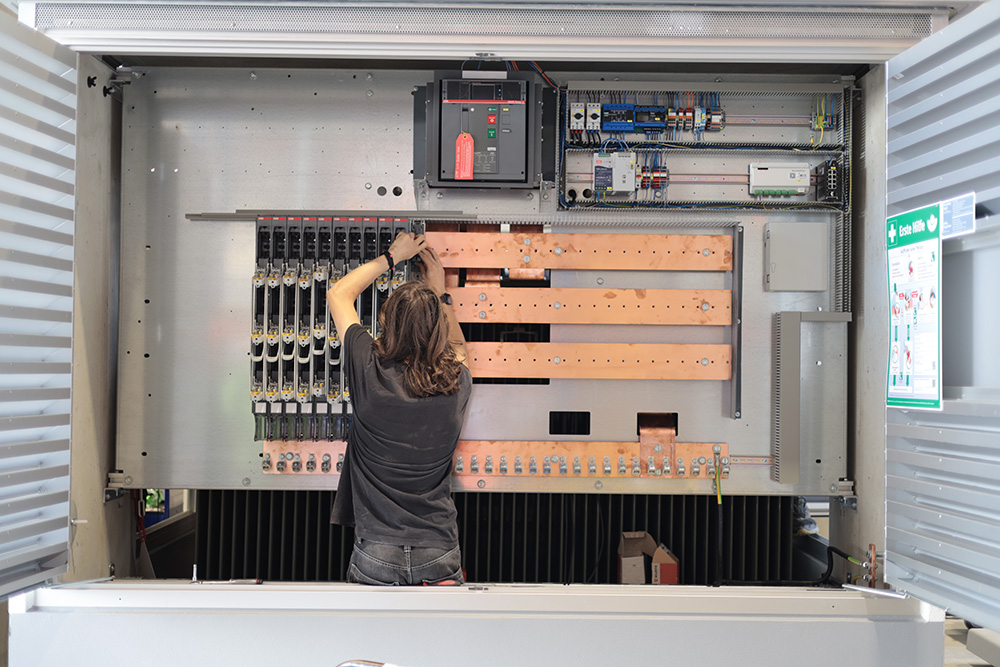

One day, a violent band of thunderstorms that stretched across almost all of Bavaria paralyzed the solar parks in rows. “We were able to detect this via our remote maintenance system,” explains Josef Ecker, “but then a specialist with the appropriate authorization to switch medium voltage had to check all the systems and reconnect them to the grid. And if there was a fault in the system, the circuit breaker tripped again and the technician had to go back into the system. And nobody really knew why. That cost time and money. So we dealt with the control and control cabinet building issues ourselves and quickly developed our own solution.”

It didn’t stop at the control cabinet. “We purchased our first prefabricated concrete houses, in which we then installed our switching devices and measuring panels. We then went to Intersolar 2019 with these complete solutions, with a very rudimentary stand and initially little attention. But we sold our first systems. That was inspiration enough to develop the topic further.”

The craftsman became an entrepreneur. He founded the company “Trafomacher“. “This allowed us to install our control and measuring systems on third-party solar parks without the name Elektro Ecker giving rise to too much competition,” says Josef Ecker, describing the background to his two companies under one roof.

When it pinches at the front

The overall concept of the switching devices includes a feed-in controller, which is installed at the feeding point. This is where the respective grid operator accesses the system to regulate it so that the electricity grid remains stable and the unavoidable fluctuations in renewable energy do not cause any damage to the grid. “But we wanted to understand what this power control unit can actually do. Initially, it was just a black box that we paid for. As project developers, we had no insight into what the electricity grid operators ultimately regulate and operate in it after our systems have been connected.”

An absurdity for a Bavarian free spirit: “So we set up our first own controller, right on the PLCnext platform from Phoenix Contact. At that time, the certified controller was not yet required. And with the help of the PLCnext libraries and the expertise of my employees, we have continued to adapt this controller to standards and requirements. Today, we use the certified Power control unit from Phoenix Contact. And we not only connect PV systems directly to the medium-voltage grid, but also sell the connections to other PV system manufacturers. 80 to 90 percent of the stations in our yard go to other system manufacturers.”

Helmut Schratzenstaller adds: “The more you deal with photovoltaics on the control side, the more complex the issues become. This also sets us apart from our competitors. Most of them concentrate on individual areas, whether controllers or control or connection. We supply the entire bandwidth from A to Z. That’s why we can also influence many parameters. If there’s a pinch at the front, we know where we can change something at the back to make it fit. This makes us fast and agile, and therefore independent.”

David and Goliath

Josef Ecker proudly adds: “In order to simplify the operation of the system, we are in the process of programming our own operating and parameterization interface. We now communicate with the experts from Phoenix Contact on an equal footing.” Marina Friedberger smiles: “Sometimes we are already a step ahead.” The graduate engineer has been part of the Elektro Ecker team for three years. Before that, she worked in automotive engineering, automating paint shops, among other things. “We are practitioners who are very close to the actual operators. That gives us an edge, even over large companies like Phoenix Contact,” she explains. Today, Elektro Ecker is one of the Solution Partners in the Phoenix Contact network, so it also supports customers in the solutions business.

The issues that the team tackles go far beyond simply connecting solar parks. The expert goes into detail: “80 to 90 percent of solar parks are based on 800 volts in the low voltage. However, these power grids must not have an earth connection from the transformer neutral point and should therefore have insulation monitoring. This is why inverter manufacturers are now demanding IT systems everywhere to enable this monitoring by the inverter down to the module level in the solar park. This is not a problem in a new solar park. But retrofitting existing systems is a problem, because the insulation material ages and becomes brittle. That’s why we want to expand the transformer station’s monitoring relay so that we can record the relay and issue an advance warning. In addition, if the circuit breaker trips, we want to be able to distinguish whether it was a frequency or voltage tripping of a subordinate protection technology or an actual insulation tripping.”

Transparent grid

Another issue is causing the self-confident entrepreneur to become furious: The energy grid operators’ sometimes less than transparent curtailment measures are causing massive losses of income for solar park operators, i.e. Ecker’s customers. “We often see these shutdowns being justified on the grounds of grid stability. However, the financial compensation that is regulated by law in these cases is not passed back to the operators, even though they would be entitled to it. This means a loss of earnings of many thousands, often even several 100,000 euros. We track the condition of the systems via VPN, record this in a database on our own portal and document this for the operators. This gives us a very good overview of what is actually going on in the network.”

“The aim is to record every five minutes what the feed-in status is and whether it is being regulated by the grid operator, and then export this data and make it available to the solar park operator. That way, at the end of the day, they know what they have really earned. And they can then go to the grid operator and insist on their financial claims. We developed the interface that we use for this based on the PLCnext Technology of the power control unit.”

This transparency was initially very surprising for the energy suppliers, continues Josef Ecker. And probably not particularly welcome either, as there were grossly unequal treatments of individual operators at very similar locations. This gives Landshut residents and their customers unexpected insights into the architecture of the energy supply, as Helmut Schratzenstaller confirms: “We see time and again that on a beautiful sunny day in Germany, around 30 to 40 percent of turbines are curtailed. In our opinion, this curtailment is too frequent and too drastic. And it varies greatly from grid operator to grid operator.” After all, there are around 850 of them in Germany, some with very different working methods.

Electricity as a commodity

And while the man from Landshut and his team are causing quite a stir on the operator side, he is already devoting himself to completely new tasks: “Our next big topic is battery storage systems. This is because they work technically with a completely different approach to the frequencies in the power grid. And the operators of utility-scale storage systems look at electricity grids in a completely different way. This is where direct marketers come into play. We also have a completely different financial presence there.” Helmut Schratzenstaller explains the new perspective: “The direct marketers, who are active on the electricity exchange, all regulate within a time window of 15 MINT. When exchange prices are super, the participating park operators can feed in fully for 15 minutes, for example. However, if the situation reverses and prices fall, the order is given to feed nothing into the grid for 15 minutes. Or to store the electricity in the battery storage system. Thanks to the “great” internet coverage in Germany, however, it can happen that the internet is completely disconnected during control commands and these control commands come to nothing. The park then continues to feed into the grid even though it is not supposed to. Or it remains curtailed even though the electricity price on the exchange is attractive again. This quickly leads to contractually agreed penalties. And these are considerable, quickly reaching five figures. For 15 minutes of incorrect feed-in! Of course, no park operator can risk that.”

“That’s why we are actually working on solutions to equip the transformer stations with Starlink modules right away in order to be reliably real-time capable,” says Josef Ecker, outlining the next challenges. “Compared to the potential penalties, the costs for the satellite network will be peanuts.”

The solutions that Elektro Ecker is developing here on the basis of feed-in controllers from Phoenix Contact are of great interest for the entire German power grid. We can therefore look forward to the next news from the farm near Landshut.