Patents are a good indicator of a company’s innovative strength. Since the days of Josef Eisert, Phoenix Contact has been a constant source of inventions that have revolutionized the world of electrics and electronics. So Dennis Geisler is following in big footsteps!

The tall lanky man could actually be a basketball player as he strolls casually through Hall 31 on his way to the pre-series production of “his” PCB terminal blocks. But for all his nonchalance, Dennis Geisler has it thick as a fist behind his ears. Or rather, in the space between the hearing aids. Because he alone developed and applied for eleven patents in 2022. Alone? “Well, of course, working on innovations is always teamwork,” he says modestly. But the flash of inspiration comes from the young engineer with East Westphalian roots. This puts the innovative free spirit at the top of the internal ranking list of patent applications.

Catching cables with the mousetrap

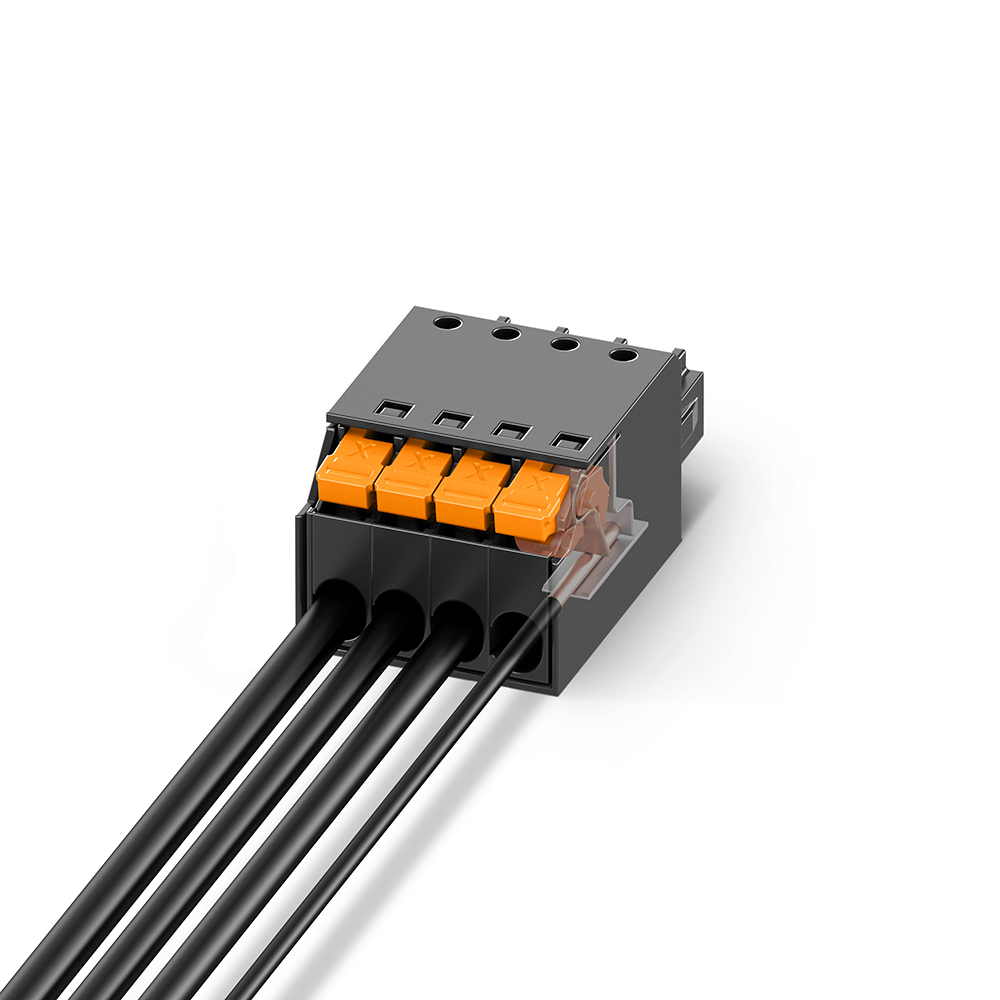

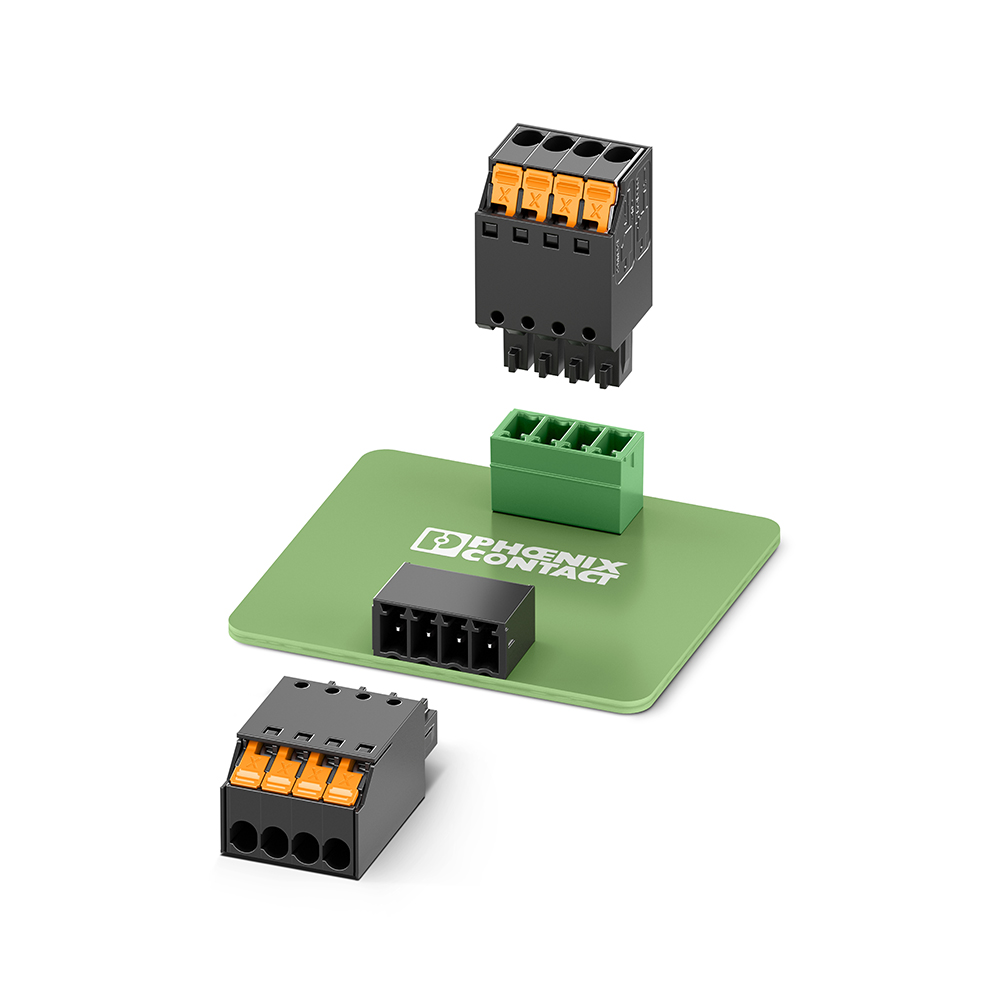

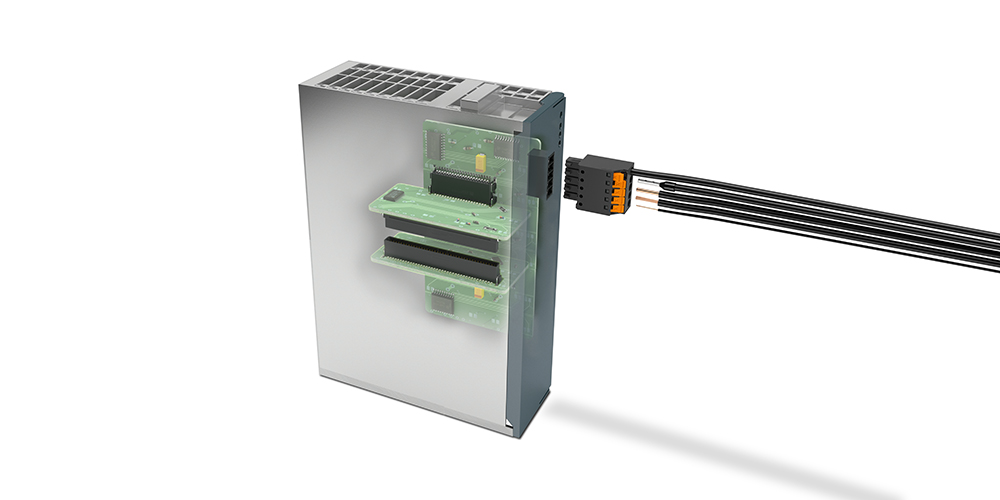

The aim of his innovative train of thought is Push-X technology and its adaptation to the printed circuit board. Push-X means that power cables are inserted tool-free into terminal blocks and securely locked in place. In contrast to the already familiar Push-in connection technology, it does not matter whether these cables have a solid copper core, whether the twisted wires are reinforced with ferrules or whether the cables are only made of flexible stranded copper wire – when the cable is inserted, it presses against a trigger. Thanks to a pre-tensioned spring, it then snaps shut and presses the cable securely against the copper counterpart so that current can flow. Can be operated and released again without any tools.

“However, this mousetrap principle doesn’t work one-to-one with printed circuit boards,” says Dennis Geisler, describing the technological challenge. “The cables used here are far too thin and therefore sensitive. With Push XPC 1.5, we are talking about a cross-section of 1.5 mm2. The sensitive cables would bend if they were to push against a resistance. A secure connection cannot be established in this way.”

An unsolvable problem despite promising approaches in other applications? At the beginning of 2022, the development order came in to make Push-X technology applicable for printed circuit boards as well. “It was clear from the outset that this project was a high priority. That’s why the development team was hand-picked. The core team is made up of five disciplines. In addition to marketing, where the requirement comes from, there is development itself, then industrial engineering for parts and tools, the laboratory for testing and finally a project manager.”

Sprinting to the product

Standard product development takes three to four years on average. This time, however, it was a sprint – just one year from development to market launch. For Dennis Geisler, this was exactly the right task: “For such an innovative product, you need people who can identify with it and are prepared to take risks. People who are pragmatic, but who also admit mistakes, learn from them and don’t try to think about all eventualities in advance and eliminate them before they occur in order to avoid making any mistakes. I was trusted as a young developer, which was of course important.”

A lightning start for Geisler, who originally wanted nothing to do with the world of terminal blocks: “I actually wanted to study chemistry, but then ended up in machine building. And that’s where product development appealed to me. Ultimately, I found my ideal field in printed circuit boards. Here you deal with various materials and their properties, and mechanics has a lot more to offer than just dealing with steel and iron. We really get the most out of things. This goes into detail right down to the microscope. A tenth of a millimeter can decide whether the connectors and connection technology work or not.”

A touch of copper

When you listen to Dennis Geisler, you can sense his enthusiasm for the little tricks and big technological leaps that he and his team have implemented. During the development phase, he registered 18 patents for the innovative connection technology, seven of which relate directly to the solution presented.

“We are currently at the stage where we can connect a flexible 0.5 mm2 cable. The cable is pushed in the feeder, but with extremely low forces. When the mousetrap snaps shut, a rotary movement follows, which acoustically indicates that it is locked. And we continue to optimize. Our goal is to be able to connect even 0.25 mm2 thin, flexible cables. That’s then just a touch of copper.

A little excursion into physics: the clamping spring we use requires a compressive force of around 20 newtons to release. However, the small flexible cables can push away perhaps 1 or 2 Newtons before they buckle under pressure. So we have to get rid of the factor 10 force somehow. And with all the tricks of lever and force, we have optimized the mousetrap principle so that it works amazingly well.”

However, pure mental work does not immediately lead to success, as Dennis Geisler also emphasizes: “I mostly design in 3D programs on giant monitors. But then I quickly lose touch with the actual size. That’s why very close teamwork with my colleagues from pre-series production is so important to me. Going over there once and consulting with the practitioners there – that grounds every idea that has taken off if it can’t be implemented on the machine in everyday life. Fortunately, we have this pre-series production here at our site.”

From the hammock to the 3D program

How does a developer come up with his ideas? What kind of environment is necessary for new ideas to be born, which are then implemented in technology? Dennis Geisler smiles: “In my private life, I’m also more of an artistic, creative type. When it comes to rules, I don’t like to be too tightly constrained. If something is too regulated, then I like to break out of it and try different approaches. And I get the best ideas when my head is free, whether in the hammock in the garden or after an intensive training session (in fact, Dennis Geisler plays volleyball in a premier league team). Turning off the PC for a while and getting away from it all – that frees up space for new thoughts.”

Nevertheless, Geisler also starts by systematically approaching a new development: “First of all, of course, you look over the garden fence, observe competitors’ approaches and think about improvements. Working on other patents is also valuable, because if you are not allowed to do something, you try to design around it without infringing the patent protection of your competitors. This gives rise to new ideas. This is how technologies are continuously improved.

Chess game of innovations

But that only works up to a certain point. And then you have to be able to detach yourself from everything you know and deal with the task again in a very fundamental way. We only had very few parts for our task, four or five. The possible combinations of how we arrange something are therefore very clear. There are seven patents in this terminal block alone. The other patents relate to solutions that we don’t actually use here, but which have arisen along the way. In this way, we naturally also secure and protect the thought model.

This patent work is a delicate, double-edged issue. Of course, the tactic of blocking patents also slows down the further development of our competitors. As a company, we want a unique position in order to achieve commercial success. But if you as a developer deal with these hurdles intensively enough, you will suddenly find other solutions. And that creates a diversity of technology that is valuable for everyone.

Of course, it’s annoying if you don’t have the patents you need to drive your own product development forward. But since everyone acts in the same way, it’s also fair because there is equal opportunity.”

Thought brakes

Tinkering with details while keeping a clear head for new ideas – what restricts a developer like Geisler? “I need some distance from my PC. If you always see the same things, you eventually become blind. A lot of Push-X was actually developed during Corona, i.e. in the home office. The first time I plugged in the cable and the closing reflex worked was at home, in front of my PC in my jogging bottoms.”

But can this pattern be repeated at will? “I’m not sure whether I’ll still be able to think outside the box in ten years’ time if I continue to work stubbornly on this topic, or whether creativity won’t be captured by established ideas,” Geissler says thoughtfully. However, he is certain of the following assessment: “No great idea has ever been born in meetings. Freedom and acceptance of mistakes, on the other hand, are decisive factors for creativity. If mistakes are not tolerated, people don’t dare to take risks, not even in product development.”

So is a change of scenery essential for successful developers? And does this inevitably lead to job hopping and thus away from Phoenix Contact? Geisler shakes his head: “First of all, there are still a few things that need to be finalized. Of course, detailed work is also part of the final phase of product development. And that’s right – after that, you have to clear your head again at some point. I need a new stimulus, a new challenge. But Phoenix Contact has so many areas and tasks – I don’t know yet whether I will then move to another development department or take on new responsibilities. The need for fresh ideas will not diminish for us either.”

Push-X in the printed circuit board

New products overview 2024