The Vinci Group is not only a global player when it comes to the construction and maintenance of buildings and infrastructure. It also operates an in-house forge. Red-hot iron, however, is not processed there. Instead, new ideas and new ways of thinking about Industrie 4.0 and IoT are forged and shaped.

What does a showroom for digital transformation need to look like? Is it even possible to represent such a comprehensive subject spatially? We visited the digital forge in Frankfurt with these questions in mind. That’s exactly what is happening there in reality.

Jörg Bastel opens the doors of his forge with a broad smile. The leather apron and hammer are missing, but sparks still fly around here, even without heavy metal. And these sparks are metaphorical, the head of the digital forge explains to us emphatically.

A total of 300 square meters are available for digital flow of thoughts. It’s enough space not only for conference areas and meeting points, but also to show exhibits that make it clear that this is not just a place for thinking, but also for bringing ideas to life quickly. And this in four core areas: Smart Industry, Smart City, Smart Energy, and Smart Building.

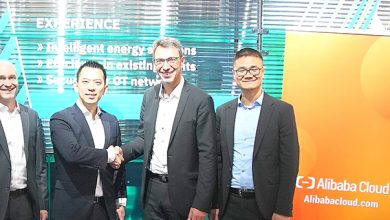

Perfect partners

This combination fits almost perfectly into the Phoenix Contact solution portfolio, which is ultimately the reason for the visit. But who is behind the digital forge?

Based in France, the Vinci Group is active in more than 110 countries. It describes itself as a concessions and construction company. In other words, it not only plans, finances, and builds infrastructure and buildings, but also maintains them. The publicly traded company with six divisions employs around 211,000 people and generates revenue of € 43.5 billion (in 2018).

The Chernobyl sarcophagus is certainly one of their most interesting construction projects in recent years. But the Vinci group also maintains 4,300 kilometers of the French freeway system and 36 international airports, including London Gatwick. And anyone driving past a major construction site in Germany that has a Eurovia sign is also crossing paths with Vinci’s entrepreneurial activities.

The digital forge is run by Vinci Energies. This division operates in 51 countries, and is primarily dedicated to installing, equipping, operating, and optimizing of energy and communications infrastructures, industrial systems, and buildings. The Actemium, Citeos, Omexom, Vinci Facilities, and Axians brands all belong to Vinci Energies.

“Those alone would be enough for us when it comes to achieving our goals,” Jörg Bastel says with a smile. The 39-year-old IT specialist describes the tasks his digital forge has been given.

“On the one hand, of course, we want to describe the possibilities of the digital transformation. We

at the digital forge see ourselves as experts who can illustrate and demonstrate a great deal, from

theoretical vision to very practical applications.”

Bastel points to a drone which allows systems to be inspected easily. “Digitalization is also tangible

here. But our main concern is actually networking with partners, which is exactly why you are here. We connect startups, knowledge, and customers, both internally and externally.”

Tangible projects

The experts from Phoenix Contact are now in the ring. Stephan Sagebiel, Head of Industry Management, and Anja Moldehn, an expert on Industrie 4.0 and digitalization topics, share a passion for new technologies and new applications. And they are immediately up to speed when it comes to building automation in the forge itself. Thanks to the open-system PLCnext technology from Phoenix Contact, there are entirely new possibilities for combining the various automation systems with their communication protocols in one handy controller and making them remotely accessible through a cloud solution.

And when it comes to process automation, which is also important for Vinci’s subsidiary Actemium, among others, joint opportunities quickly become tangible. “In mid-October, we will be hosting a

hackathon together with Vinci where we will bring our developers together and program an innovative pump monitoring system in a very tight timeframe.

This will also be on the PLCnext platform, which can easily handle high-level languages,” says Anja

Moldehn enthusiastically.

We are already there

Stephan Sagebiel explains the special situation in the cooperation with the digital forge. “We are meeting experts who do not just view the tasks from a theoretical point of view alone. Here, there is always a current practical application, along with a real client, behind the respective task. That’s what makes the cooperation with the digital forge so interesting for us,” he says, and heads for the control cabinet below the pump exhibit. A broad grin appears when he opens it, because Phoenix Contact already controls what happens there.