The electricity war between direct and alternating current was actually already decided in 1890. But after more than 130 years, the loser is gaining new significance. Dr. Martin Wetter and Dr. Christian Helmig have set out to unearth the treasure of direct current.

When you talk about DC on the Phoenix Contact campus, the first thing that comes to mind is the connection technology for printed circuit boards, the Device Connectors. This is the name of an entire business unit at the Blomberg-based electrical engineering company. But DC can also mean something completely different, and that’s exactly what it’s all about when you talk to Drs. Martin Wetter and Christian Helmig. DC is known worldwide as the abbreviation for direct current.

It is everywhere

It’s not just their distinctive hairstyles or penchant for blue suits that unites the two figureheads of DC technology. Their common background is much more important. Both are graduates of the Dortmunder Lehrstuhl für Hochspannungstechnik in Germany, where they also completed their doctorates and worked together. Wetter, from Münsterland, moved to Blomberg in East Westphalia in 1997, and Helmig, from Westphalia, followed five years later to Phoenix Contact.

Even though they both work in different units of the company, their passion for the transmission and application of direct current currently brings them together. This is because they both firmly support Phoenix Contact’s mission statement, the All Electric Society. And direct current, they are certain, can make a valuable contribution to the success of the sustainable energy revolution.

We are actually constantly surrounded by direct voltage in everyday life. “Every electrical device with a display, from washing machines and smartphones to car electronics, contains direct current. Every small electric drive usually works with direct current and every battery stores direct current. There are only very few devices, such as old toasters or irons, that work directly with alternating current,” explains Martin Wetter. And Christian Helmig adds: “Thanks to renewable energy generators, especially solar, direct voltage has become a big issue again. Whether in solar modules or wind turbines, the energy captured is first converted into direct current. And in electric vehicles, batteries drive the wheels with direct current.”

Advantage DC

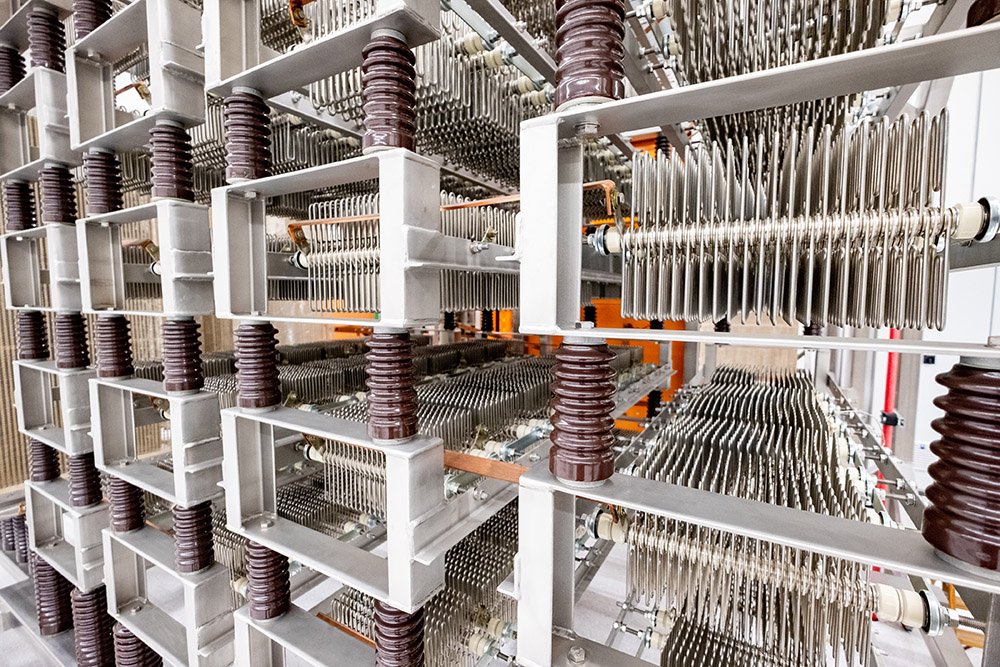

Three major arguments play into the hands of Thomas Alva Edison’s late successors: efficiency, storability and resources. It is immediately obvious that every time energy is transformed, some of it is lost as heat. If electricity is generated by wind or sun, it is initially available in direct voltage. The conversion to alternating current “eats up” around 20 percent of the original energy.

And if you set things in motion using direct current, you can easily recapture the excess kinetic energy through recuperation. “This is particularly easy with direct current. And this is not only important for e-mobility, but also in many industrial areas such as high-bay racking systems or industrial robots. Energy is recovered when movement is reduced,” adds Innovation Manager Wetter. “Efficiency is therefore one of the central issues when it comes to the increased use of direct current.”

The second major issue is direct storage. Energy from batteries is direct current. Direct current systems can therefore store or retrieve energy directly in batteries without conversion. This is relevant where systems must not fail, such as data centers or production facilities, in mobility or in process control systems.

The third major advantage is the saving of material, as the required cables have significantly smaller cross-sections. This is particularly important for industrial production facilities. Dr. Wetter describes a specific application: “A high-bay warehouse that works with direct current recently went into operation. Thanks to recuperation, the conveyor baskets that move downwards provide the energy that allows the other baskets to move upwards again. As a result, the required connected load, i.e. the amount of energy, has been reduced by around two thirds compared to a conventional AC connection. This really saved a lot of money on the connection.”

Advantage AC

Alternating current, on the other hand, has great advantages when transmitting energy over long distances. Dr. Wetter explains: “If I want to transmit a certain amount of power, I need current multiplied by voltage. If I want to transmit a lot of power, I have to increase the current or voltage or both. However, the transmission losses on such lines depend solely on the current. They even increase quadratically, i.e. twice the current equals four times the losses. This is why high power is transmitted over long distances with alternating current and high voltages. This minimizes transmission losses. The conversion is simple and extremely reliable with appropriate transformers.” Alternating current is therefore a given in classic distribution grid technology with a few large power stations and star-shaped distribution. Direct current is therefore more of an issue for local “island solutions”.

But working with alternating current has another very important advantage. Martin Wetter explains: “Theoretically, there is nothing that would not work with direct current. But what we have achieved with alternating current is an extremely high safety standard. By way of comparison: in Germany alone, around 3,000 people die in road traffic accidents every year. But only 30 deaths from electric shocks, despite the enormous spread.”

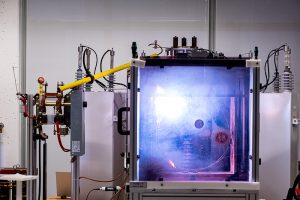

Why is it that dealing with direct current is still the domain of specialists? Christian Helmig explains: “The real difference between DC and AC in everyday life is the lack of current zero crossing. If you disconnect an operating device from the mains in an AC voltage network, an electric arc occurs. However, this is hardly noticeable as it only lasts a fraction of a second. With direct current, you have to be much more vigilant. Disconnecting a live appliance from the mains triggers a dangerous electric arc that poses a massive risk to both the user and the material. That’s why one of our product development goals is to achieve a similar level of safety with direct current technology as end users are used to with alternating current.”

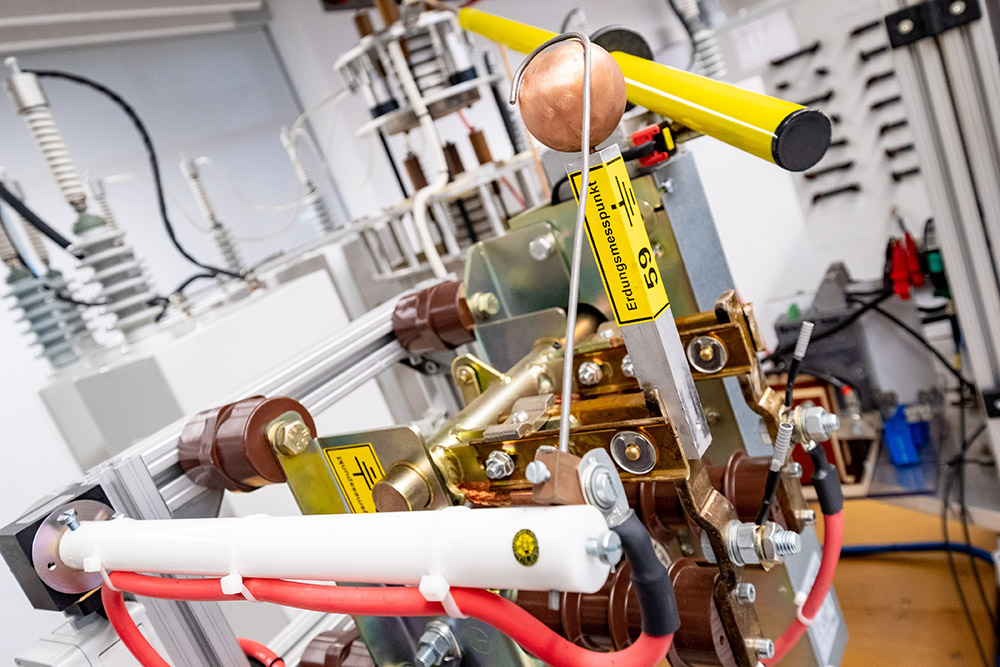

Plug with intelligence

Christian Helmig pulls out a plug and places it on the table: “But thanks to new power electronics, we now have ways of harnessing the benefits of direct voltage again. And we also have the first products, such as this ArcZero DC connector, which are specifically aimed at the direct use of direct current. This is already being tested in pilot systems in some companies. But there is still a lack of standardization to ensure that the devices work together.” Dr. Helmig points to the connector: “This is the first connector that we have developed just for DC. It has an integrated circuit that recognizes the contact. If I pull the plug under load in a DC power grid, an electric arc is created here too, but it is only minimal as the current triggers the circuit, which then switches off immediately.”

The product looks similar to a classic plug for alternating current, but is slightly longer due to the integrated circuit. Wetter: “This shows why we can’t convert everything to DC straight away. A simple plug and socket are much more complex in terms of design and cost to achieve the same handling. The world of alternating current is simply better established. We are therefore also founding members of the Open Direct Current Alliance (ODCA), in which more than 40 companies have already joined forces to develop standards for devices in the same way that alternating current has for a long time. The system concept is more important than the individual competition of innovations.”

A new electricity war?

However, Wetter does not see any competition with AC systems. “AC technology is really good and mature. I see the new developments in the direct current sector as an exciting and growing, but niche topic. Where direct current has its opportunities and strengths, that’s where it will come. But everything that works with alternating current is so mature and established that a fundamental change in our energy structure is unthinkable.”

“Whenever new buildings are constructed, such as our current production building 60, where there is photovoltaics on the roof and charging stations in front of the building, where storage elements are used, machines are driven and I have a great deal of freedom in terms of planning, direct current becomes an exciting alternative,” says Christian Helmig, outlining his own pilot project. “In Building 60, we are working on a DC subnetwork with the aim of extending it further into our own machine building and production at some point. We initially worked with the Fraunhofer Institute on the planning. And then we brought in our colleagues from our own facility management team. However, this also shows that dealing with DC grids is still far from being part of everyday life. No normal electrician dares to do it yet.”

But Dr. Helmig is confident: “With increasing show cases, it is becoming easier and easier to use this technology. Incidentally, this was also true for our own colleagues here at Phoenix Contact, but now customer interest is also increasing. We have a lot of visits, because many of our industrial customers want to find out more about the experiences we are having with Building 60.”

The “direct current twins” have no doubts about the success of their mission: “We believe that this technology makes sense. The advantages are obvious. It fits perfectly with our vision of an All Electric Society, so the products we are developing are also an investment in our future.”

Der Podcast zum Thema

Phoenix Contact Gleichstromnetze

Phoenix Contact DC Steckverbinder