For those who did not yet know that Phoenix Contact also manufactures hand tools, the following lines are certainly of interest. We were not only interested in the Scandinavian place of origin, but also in the performance of the metal Swedish snacks. Let’s go and test the Crimpfox Duo 10 at the practitioner!

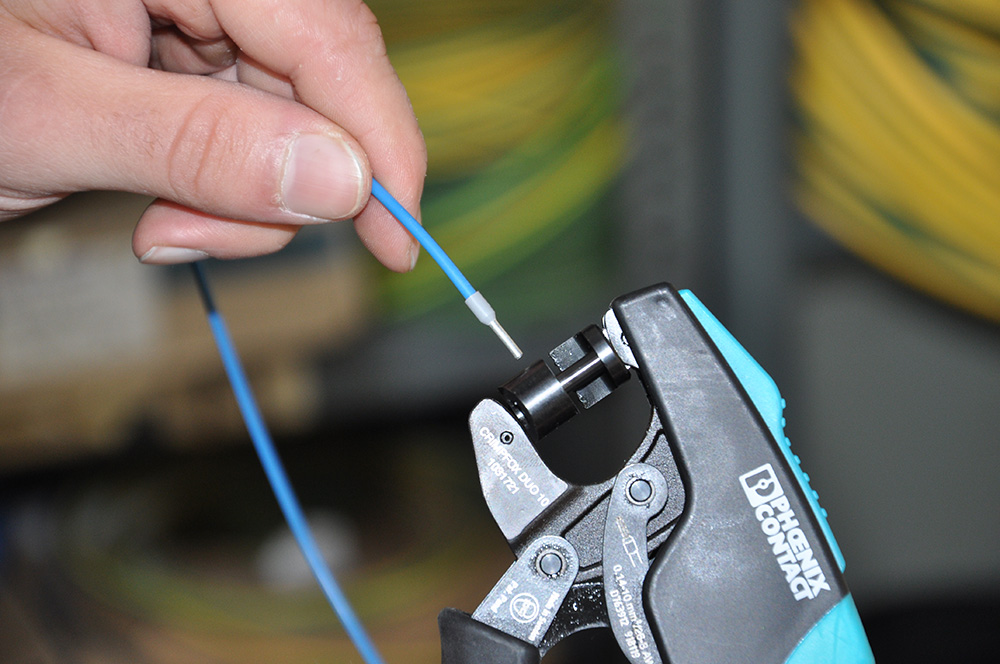

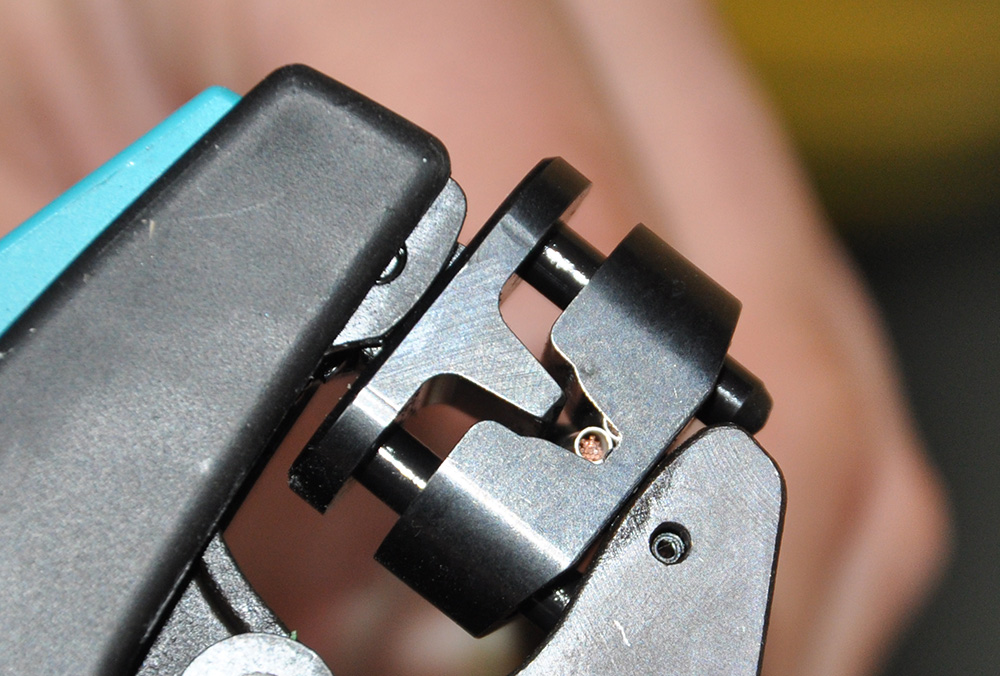

Click, click, and click again – Julius Stückemann is fascinated. The junior boss of the traditional Bielefeld company ITS Stückemann turns the die of the Swedish Crimpfox Duo 10 by 90 degrees again and again. “This is really ingenious, we have never seen anything like this on other crimping tools before.” This will not be the only praise uttered by experts during this tool test.

Swedish steel for the control cabinet

The Crimpfox Duo 10 is made in Älvdalen – the headquarters of the toolmaker Pressmaster Pressmaster. Since 1976, the Norsemen have been manufacturing precision tools here, in the heart of Sweden, which are pioneering, especially for the electrical trade. As early as 1973, the C-Frame, the world’s first modern crimping tool with ratchet mechanism, was invented and patented, at that time still in Stockholm.

In 1975, Pressmaster went one step further and developed the self-adjusting stripping tool. The Pressmaster Tool production facility was then opened in Älvdalen in 1976. Numerous other new developments and patents relating to cable processing followed. Then, in 2012, Phoenix Contact took over the innovative tool forge.

It has to be a Heinrich

The company ITS Stückemann GmbH & Co. KG in Bielefeld is a real company with a long tradition. Already since 1920, the East Westphalians have enabled a smooth flow of electricity and energy, always conducted by a Heinrich, because the founder as well as the current head of the company and one of the two future company directors bear the same first name.

38 employees work in the electrical, plumbing, and heating sectors. The tasks range from classic installation work to ultra-modern smart home applications, the integration of renewable energies into energy and heat supply systems, and e-mobility solutions – both private and commercial. The company is working at full capacity; a new building will make room for state-of-the-art technology, a spacious showroom, and special training facilities.

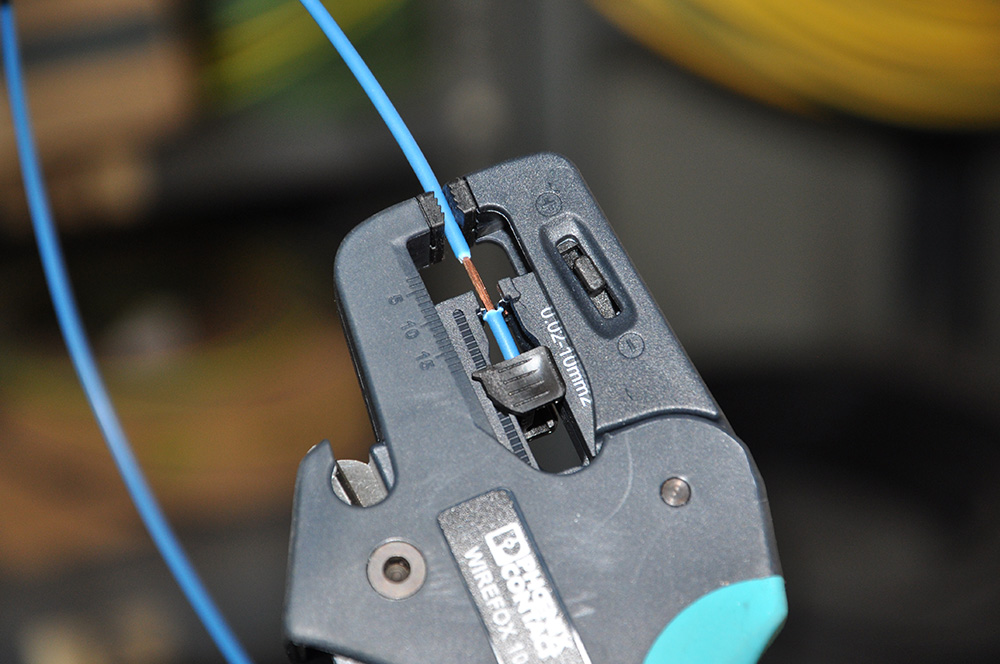

Just the right place to take a closer look at two pairs of pliers from Phoenix Contact. This is because the the fact that Phoenix Contact has much more than just terminal blocks and other well-known products in its range, but also manufactures and sells its own tools, is often new even to experienced professionals from industry and trade. The “Crimpfox Duo 10” and the “Wirefox 10” were therefore packed up and handed over to the Bielefeld company for a 14-day endurance test. For two weeks, the set of crimping and stripping pliers accompanied installers and then were critically assessed. On the construction site, everything is equal at the outset. And against the top dogs of the tool industry, newcomers traditionally have a hard time, especially in the trades.

In practice

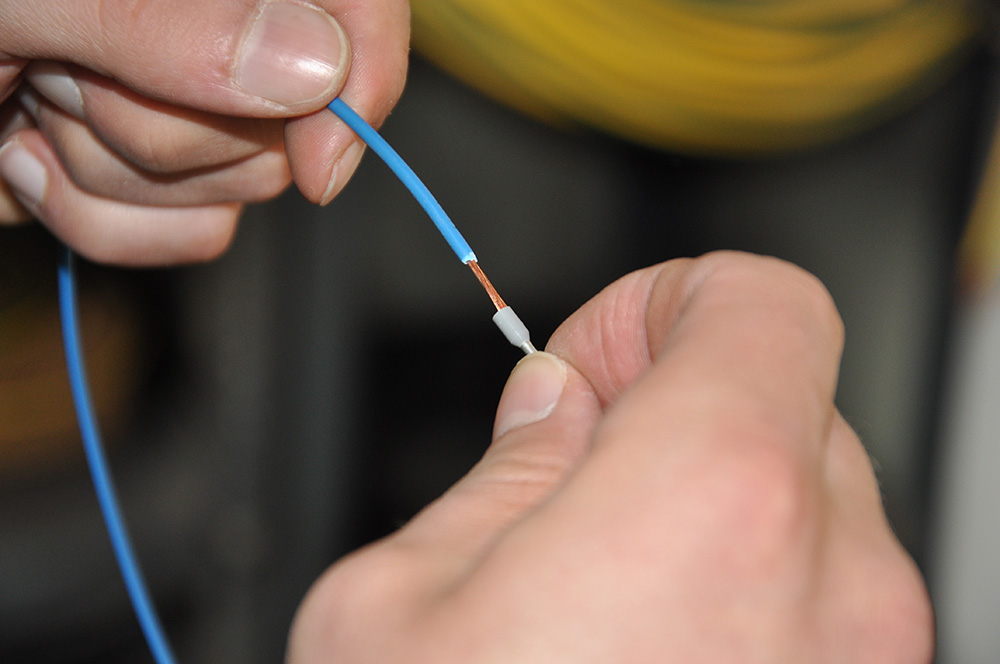

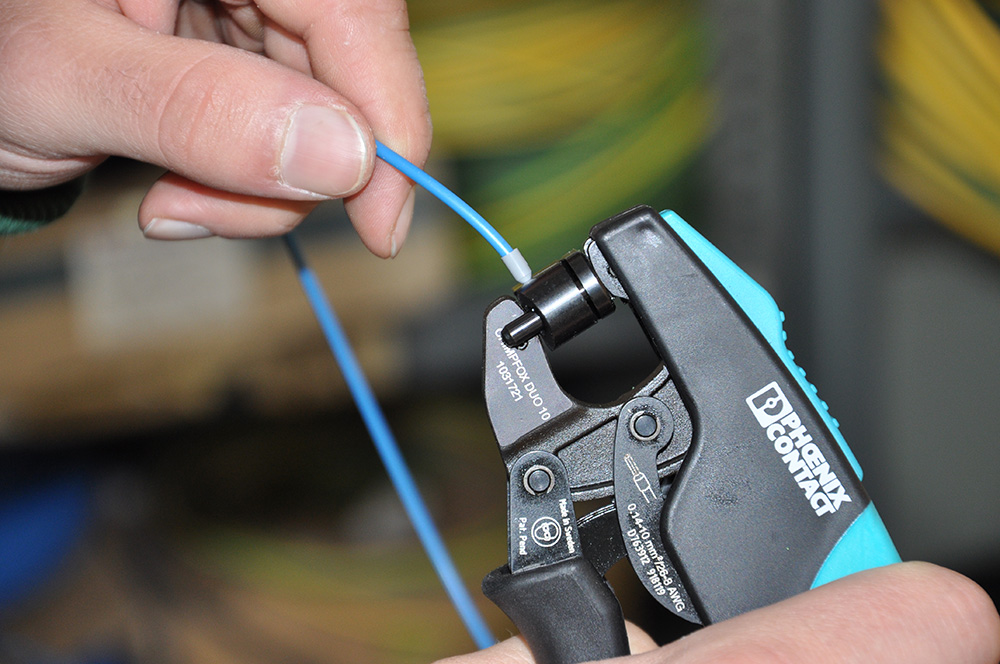

A good two weeks later, Julius Stückemann clicks the rotating die of the Crimpfox Duo 10 back and forth. The 28-year-old future company boss, who will share his task with his brother Heinrich, is also responsible for marketing at Stückemann. But the smart young entrepreneur is also at home in the workshop and on the construction site, as he demonstrates at the apprentice workbench. He quickly snatches up a few cables, sets the pliers in the right light, and then demonstrates what his colleagues experienced “in the wild” with the elegant Swedish pliers.

“Although the Wirefox 10 stripping pliers are not a groundbreaking new invention, they impressed our employees with their excellent handling and the convenient and rapid stripping-length adjustment function. However, it is almost too good to lie around in the dust and dirt inside a toolbag waiting to be used – our technicians would expect problems with the mechanics in the long run.

The Crimpfox is altogether different. It impressed everyone. It quickly became clear to us that it would only be under- utilized when used on standard construction sites in new buildings. But my colleagues had to work on new installations in older plants several times. Wherever the wiring in a control cabinet has to be changed from old to new, you often have the problem that the old cables are very short. The swiveling crimping die is a fantastic solution to this problem.”

However, Stückemann does have one point of criticism: “Some colleagues would have liked the pliers to crimp up to 16 mm2, but they only work up to 10 mm2 cable cross section. That is sometimes a bit small.” But Julius Stückemann and his colleagues did not want to release the pliers duo again. “They stay here!” Which is probably the best compliment for the steel Swedes from Älvdalen.

phoenixcontact.com/crimpzangen