Visitors to this year’s Wind Power Technology Congress were fascinated by Jörg Spitzner’s vision of a wind turbine that not only generates electricity, but also extracts CO2 from the air.

The third Phoenix Contact Wind Power Technology Congress was held in Blomberg in February 2019. The subjects were enthralling, the speakers top-class.

One presentation, however, was so visionary that the author of this article decided, after consultation with the specialist colleagues (“Is he crazy, or is this to be taken seriously?”), to find out more about “Blancair” and the CO2 vacuum cleaner on the wind turbine by going to the site in Hamburg Finkenwerder to talk to the person behind this vision.

Award-winning restless spirit

If you were to call anybody Gyro Gearloose, the Walt Disney character, then Jörg Spitzner would be right at the top of the list. And quite literally, because he truly is an expert in gears, gyros, injectors, and aerodynamics. After all, Spitzner worked for the aircraft manufacturer Airbus for many years. But at some point, he found the corporate constraints too much for his ambitious free spirit – and founded his own engineering firm, Spitzner Engineers, in 2007. The main customer: his former employer, who is based just round the corner here in Finkenwerder.

From wings to rotor blades

It is, however, not very safe to stand on just one leg. Jörg Spitzner and his team are accomplished aerodynamic engineers. There is not a great deal of difference between the wings of an Airbus and the rotor blades of a wind turbine. Spitzner dared to bridge the gap. “We have been applying the technology of aircraft manufacturing to the wind industry since then”, explains the 56 year-old engineer.

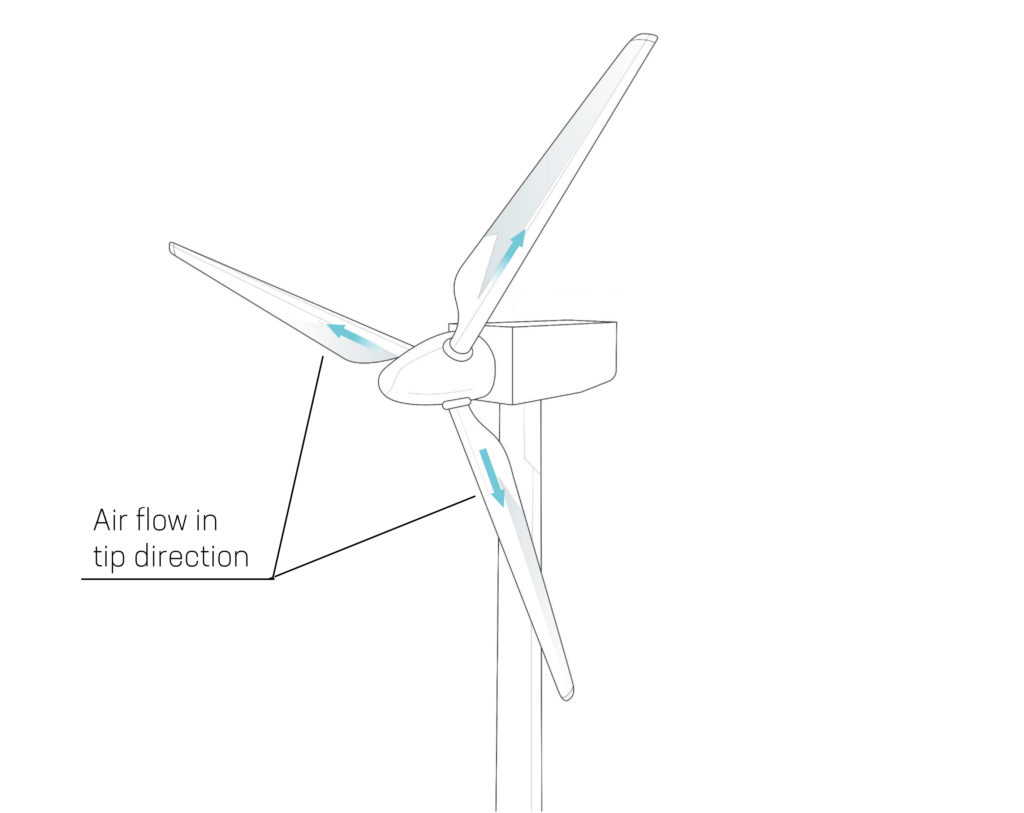

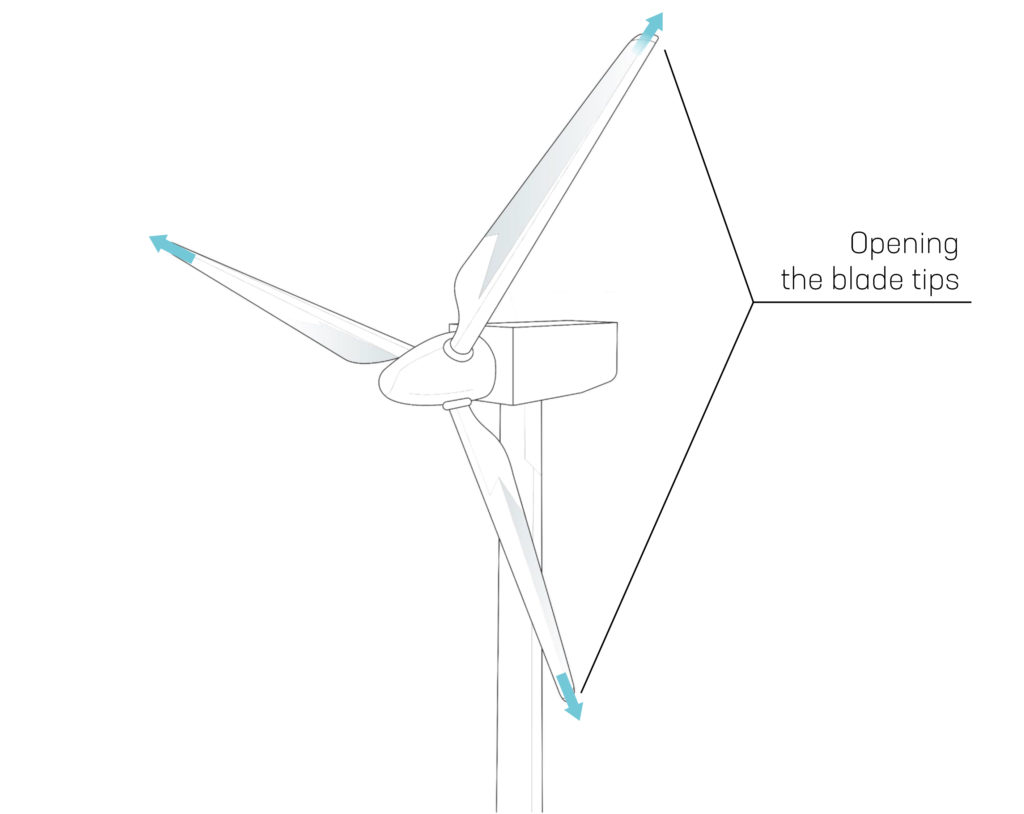

In 2009, Spitzner Engineers developed the principle of airstream control on rotor blades. “We open the tip of the rotor blade and, by drilling small holes on the root of the blade, ensure optimized aerodynamics. The rotational energy alone creates an airstream that significantly increases the energy yield of wind turbine generators with these modifications.” As a part of the project, they also equipped the rotor blades with winglets and a sawtooth-like rear edge.

During the next development project, an innovative de-icing system for rotor blades, Spitzner found the right partner in Phoenix Contact. “The idea, calculations, and commissioning came from us. But we aren’t electronics engineers – this is where your colleagues at Phoenix Contact came in.” The “Anti- and De-Ice Operating System” (ADIOS) is now almost ready for series production. The first test systems with electrically heatable coating have been set up.

The CO2 vacuum cleaner

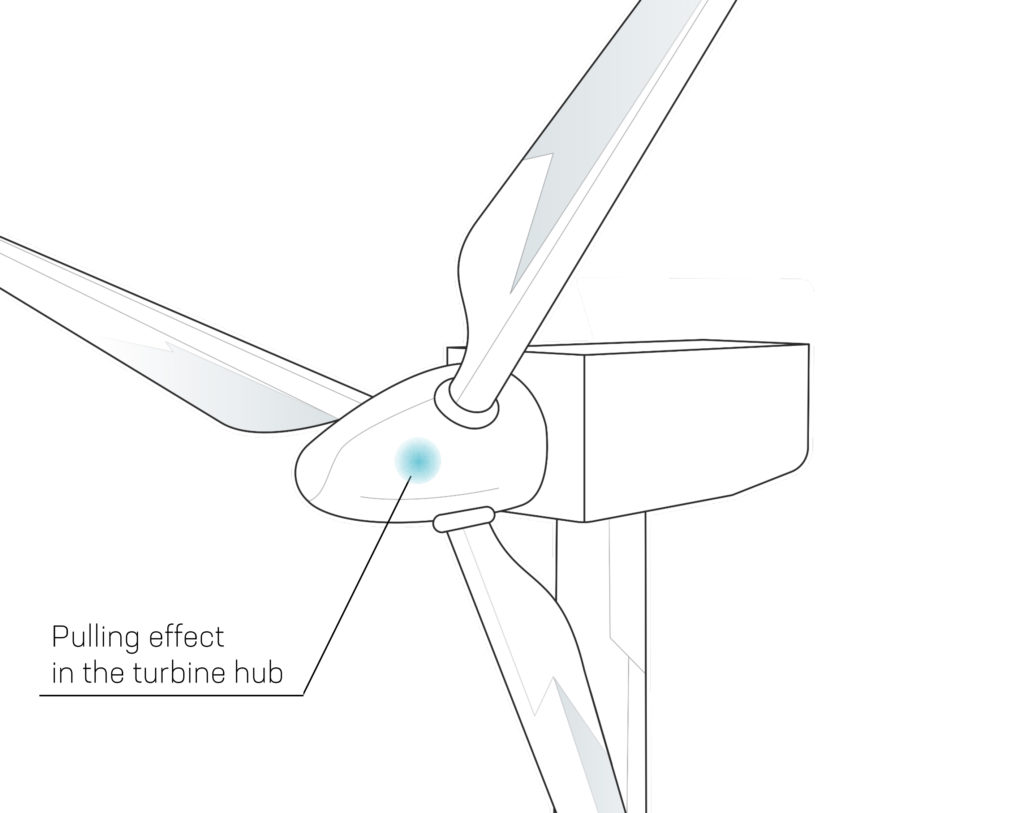

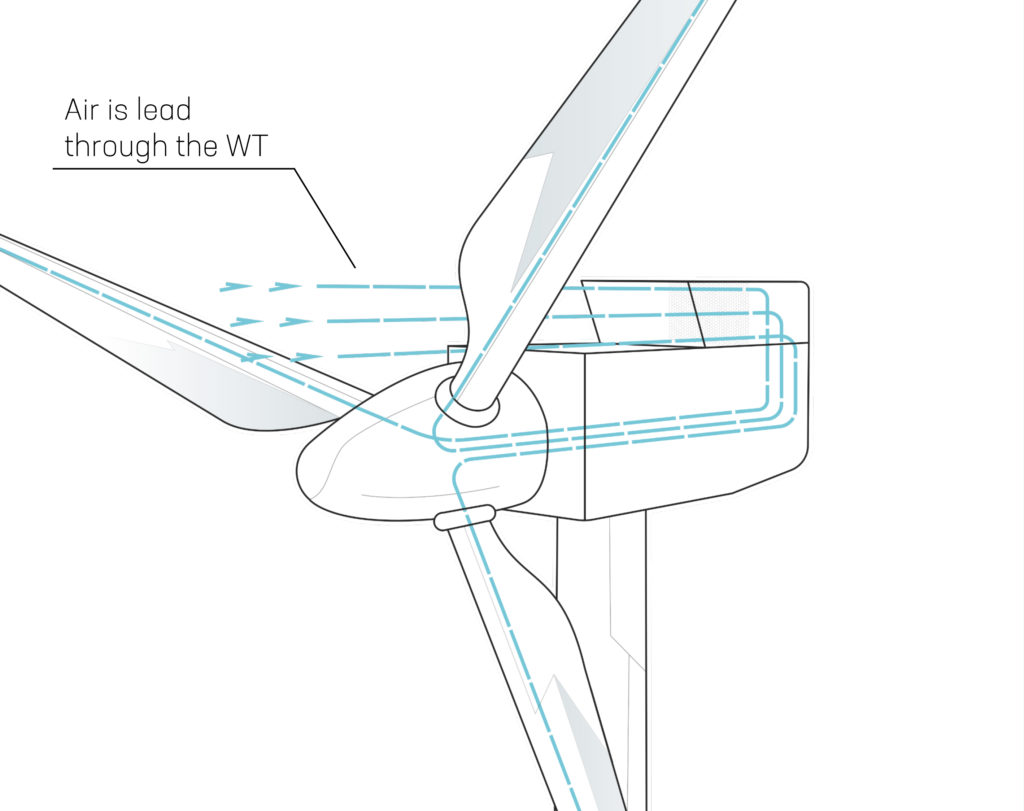

The latest development in the field of wind power originates from the experience gained in rotorblade optimization. “When you open up the blade tips (1), the air which is initially still flows outwards when motion is applied (2). The power generated is enormous. We then wanted to find out what the effect of opening up the root through to the hub of the wind turbine (3) would be. From this, we discovered that the circulation generated would be perfect for drying the air (4). Indeed, condensation is a huge problem, especially in the offshore sector.”

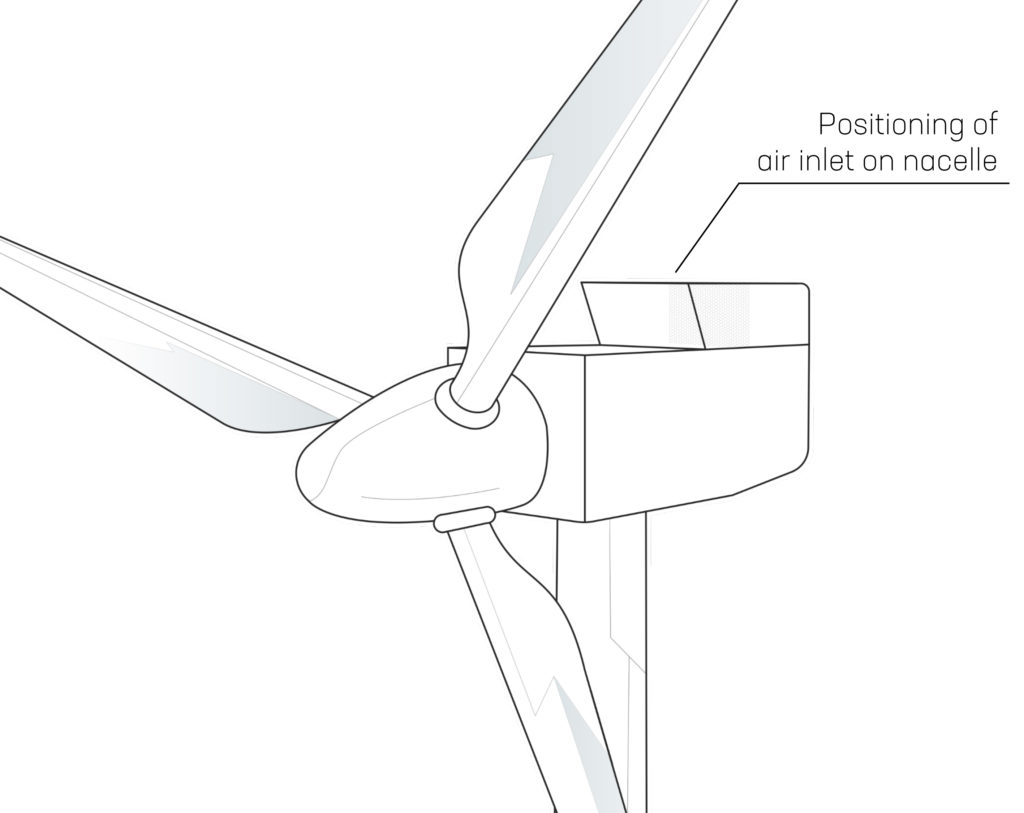

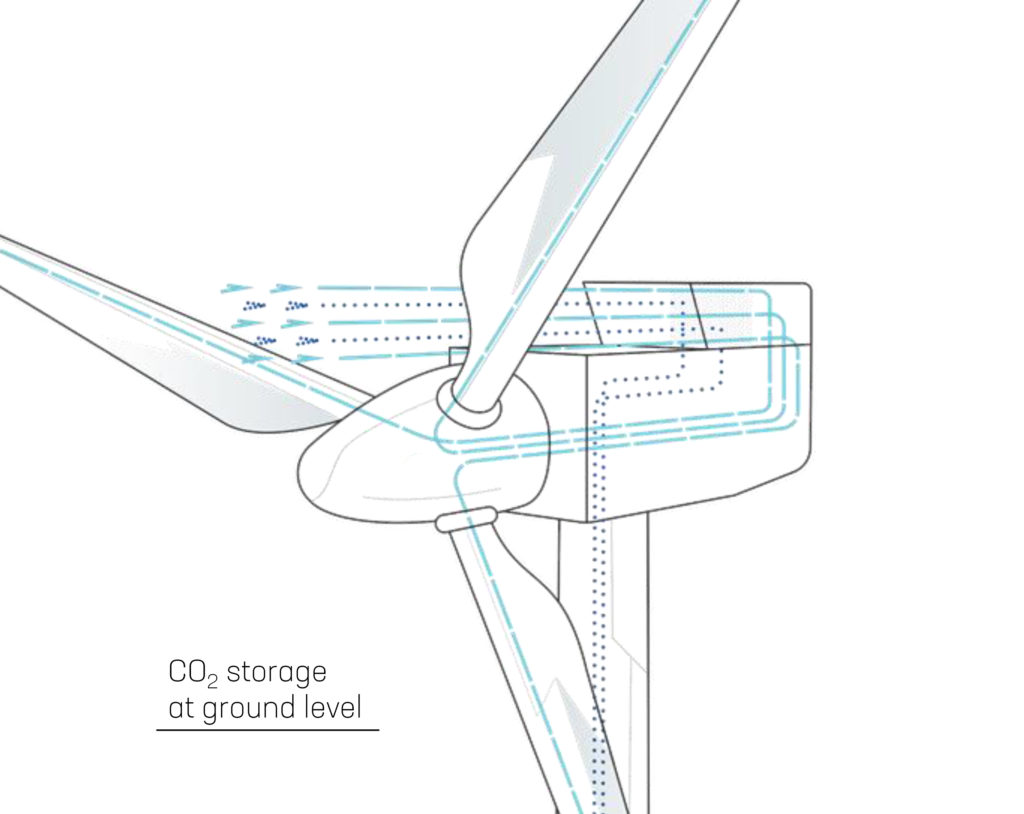

But Spitzner and his colleagues were thinking one step further. “If the airstream generates such power, then we should also be able to filter it (5). This ensures additional drying in the system. And – now we come to our Blancair approach – we could also filter CO2 out of the air (6).”

The background to the idea was that despite all climate protection measures, far too much CO2 is emitted into the atmosphere worldwide. “This is precisely where we started. With ‘Blancair’, we have so much energy available that we can draw air in and filter it. In this process, we can separate and collect the CO2, and make it processable as e-fuel – or dispose of it.”

This is a win-win situation!

Jörg Spitzner is a visionary, but not a fantasist: “Naturally, in the beginning we also asked ourselves whether this was even possible. How sort of size does a retrofittable system of this kind have to be? Would it fit in a nacelle?” Today, Spitzner is absolutely certain. “It’s a win-win situation. The idea truly breaks the mold. And has now been patented.”

In response to the question of whether Spitzner sees himself more as an engineer or a climate saver, he smiles. “Both are true. Above all, we have ingenious ideas. But we also have a social responsibility. For example, we reject any orders from the defense industry.”

Anybody who gets to know Jörg Spitzner will quickly cotton on to the fact that one or another of his and his team’s ideas is ready and waiting for the next presentation – perhaps at the 2020 Wind Power Technology Congress in Blomberg…