Off we go to Blomberg, on the hunt for the digital twin. Here we find the next trace of the digital clone. We’ll start at a field office, not directly on campus.

The Lean Value Chain department is hidden in a small industrial area with a facade that, at first glance, appears unimpressive. The office manager, 33-year-old industrial engineer Marlies Achenbach, greets us with the words, “You’ll only find a part of the twin here at best.”

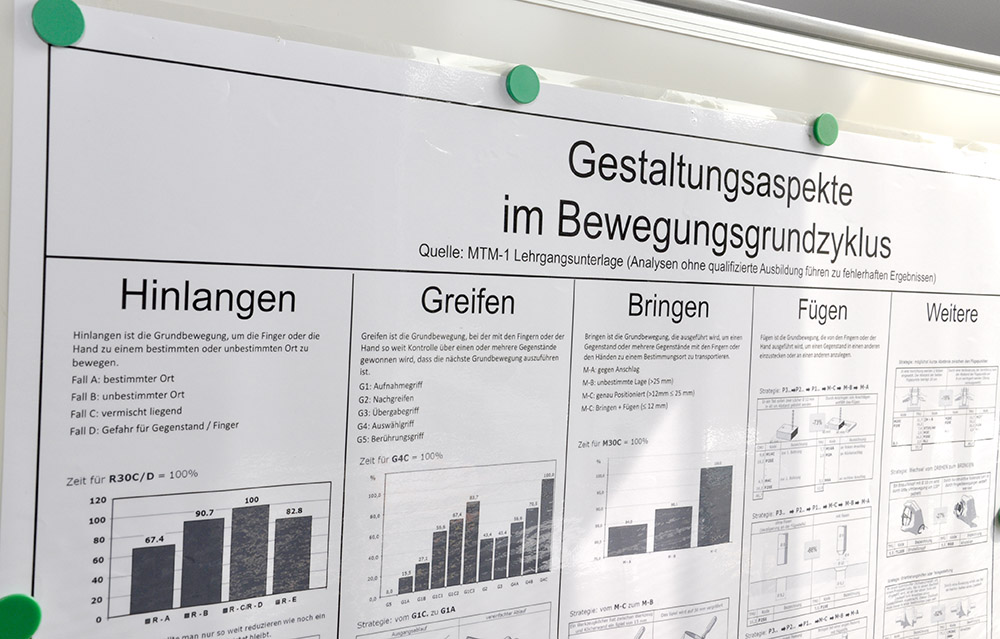

But this part, as we then learn, is a particular- ly interesting one. This is because the Lean Value Chain department is dedicated to optimizing processes, especially in production and logistics. “We advise and train our colleagues very tangibly, and also with a stopwatch in hand when examining their processes. Making things lean means making them efficient – and that is exactly what we aim to do.”

This is by no means just a matter of savings. “We try to achieve optimized processes in production.” In doing so, the Lean Value Chain department accesses data from the Manufacturing Execution System and, ultimately, merchandise management data from the SAP environment.

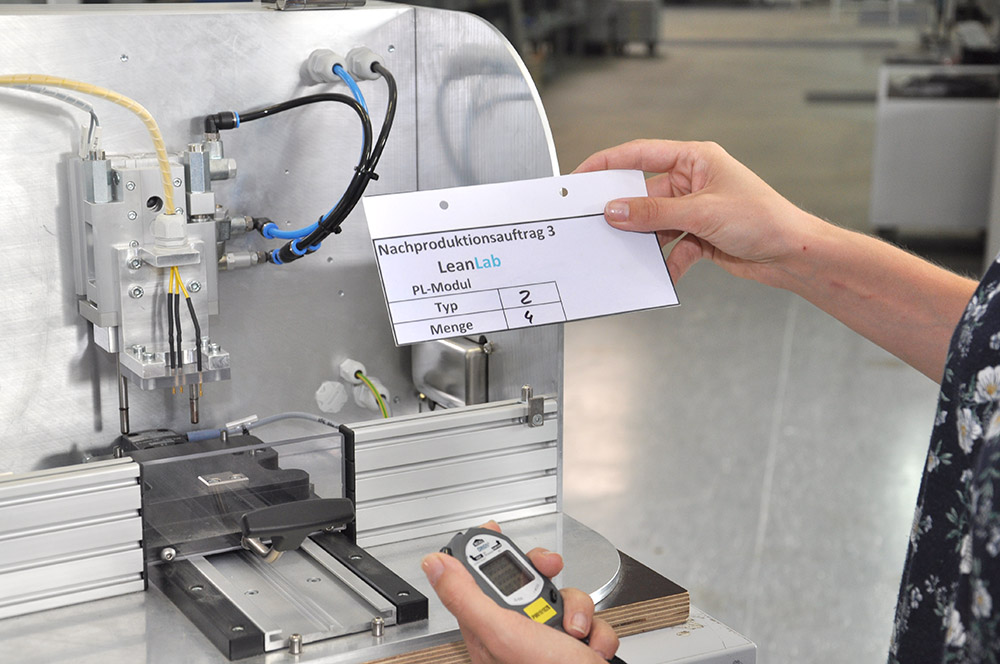

“We don’t look at the processes in our own production,” explains Marlies Achenbach. “Instead, we also support our partners in the supply chain, the suppliers. An extended workbench is a concrete example. We deliberately trained the partner company in the design of lean production processes and coached it during the first implementations. In part, we also simulate material flows in a digital factory during our optimization work.”

So we find not just one individual twin here, but rather an entire group of them? “Exactly, our ideal is a digital factory in 2D or 3D, where CAD data from machine building and SAP data from the enterprise resource planning system come together, enabling simulation runs for optimized production processes.”

We feed it

We train it

We control with it

We print with it

We’ve got it!