On-site-visit ice rink. Normally, the professional ice hockey players from the traditional Swiss club EHC Kloten race across the ice here. But instead of the black hard rubber puck, today it’s all about intelligent building automation and suitable control systems.

Thomas Stucki can’t get the grin off his face today. The systems consultant from Phoenix Contact Switzerland is a real fan of the ice hockey club EHC Kloten from the canton of Zurich. His ice comrades have been playing in Switzerland’s top division, the National League, again since 2022 following their successful promotion. For him, a visit to his home stadium, the Swiss Arena, is therefore not just a professional pleasure.

And today is also a home game for Simon Züger. Although he describes himself as a fair-weather fan, in his role as Director of the Schibli Group’s automation department, he knows the building complex on Schluefweg – where the Schibli Group has been involved in electrical engineering for many years – like the back of his hand.

Building automation on black ice

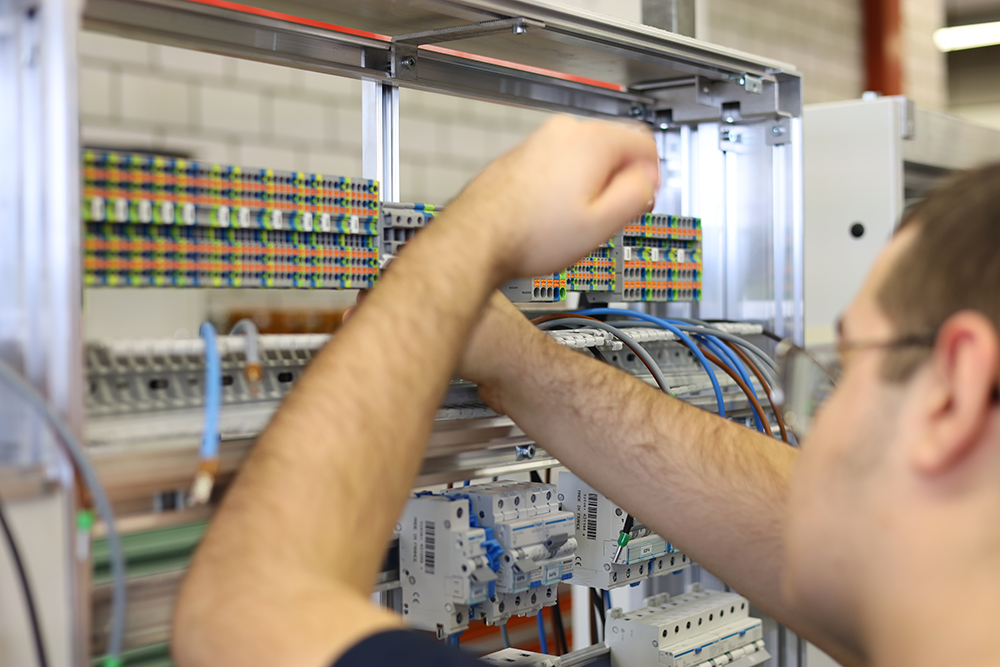

“In 2020, we as the Schibli Group not only renovated the lighting in the Swiss Arena and equipped it with a new control system, but three years later we were also responsible for the entire electrical engineering when the new training hall, the Schluefweg Halle, was built in the immediate vicinity.” He speaks and carefully feels his way towards the boards. The photographer has his shots in the can, and we are happy to be able to leave the skating paradise without an accident. Simon Züger leads us to the basement of the Swiss Arena, which can hold around 7,600 spectators. This is where the building technology is housed, including the control cabinets that bring the ice hockey stadium to life.

On the way to the catacombs, Züger explains: “Before the renovation in 2020, the Swiss Arena was still using energy-guzzling mercury vapor lamps. In addition to the lack of energy efficiency, there was another problem. If the lamps failed, it could take up to 15 minutes before they could be switched back on. For a stadium that also hosts international sporting events and regularly hosts TV broadcasts, this was no longer in keeping with the times. We won the contract as the Schibli Group and installed new LED spotlights that could be controlled using DALI technology. Although the DALI technology would also have worked with conventional ILC controllers, we wanted to work with the innovative PLCnext Controllers from Phoenix Contact. They had just been launched on the market at the time.”

Partner at eye level

The expert praises the cooperation with Phoenix Contact in particular: “For one thing, Phoenix Contact Switzerland is based just around the corner. If necessary, someone is quickly on site. Phoenix Contact also has its own warehouse here, which has helped enormously in recent years when supply chains have suffered everywhere. And then the cooperation with the support team in Switzerland and at the German headquarters is excellent.” Simon Züger explains that the DALI modules initially only ran in a beta version on the PLCnext controller. However, thanks to the support of the experts, it was possible to develop a finished version of the software in a very short time, which was then successfully implemented in the stadium. “We worked on an equal footing with our colleagues in Bad Pyrmont and were able to incorporate our requirements and the customer’s needs. We really appreciate this partnership-based and uncomplicated cooperation with Phoenix Contact.”

From 2021 to 2023, the Swiss Arena was expanded with the addition of a new training hall, the Schluefweg Halle. The new building was urgently needed, as the old ice rink was completely full. Some of the children’s and youth groups were already training at 6 am. The training hall is a building with a modern design – lots of glass, wood and concrete characterize the look. The technology that controls the interior of the arena matches this. “Schibli was able to carry out the entire electrical installations for the new building, including the integration of the control systems. Based on our experience with the replacement of the LED spotlights in the Swiss Arena, it was clear that we would once again rely on the Phoenix Contact solution with PLCnext Technology. We used a total of nine controllers, which are responsible for the entire decentralized light control system.”

Proud in-house development

The Schibli Group is not only adept when it comes to lighting. A good 550 employees take care of everything in buildings that has electricity flowing through it. And that’s quite a lot, as Thomas Stucki knows. He doesn’t just look after Schibli when it comes to the ice stadium: “From the feed-in and automation of large PV panels on the roof to their interaction with electromobility solutions in the same building – our everyday lives are becoming increasingly electrified. This is exactly where Schibli is at home, using products from Phoenix Contact. And it’s not just about using our components and controllers. Simon Züger and his automation team also develop their own solutions based on PLCnext Technology.”

Simon Züger adds: “We use the secure apps on the PLCnext Control, the mG Secure Cloud Connector and the ProfiCloud from Phoenix Contact to communicate with the outside world. This allows us to install all software updates via the Proficloud, which of course makes maintenance much easier. This is ideal for both us and the customer.”

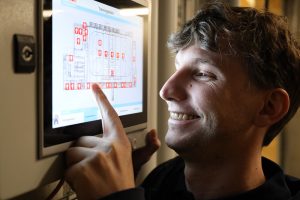

Züger is particularly proud of an in-house development: “We developed the sHub maintenance planner and installed it on the PLCnext Control. The sHub maintenance planner visualizes the status of the system. This allows you to intervene if necessary or in the event of error messages, for example. Faults can be forwarded directly to the responsible service technician. Or, thanks to precise knowledge of the various system components, predictive maintenance can be planned, including the notification of maintenance personnel, in order to prevent breakdowns. This is an immense advantage for customers who have a high-production plant, for example. Notifications are sent by email or can be integrated directly into a higher-level control system via OPC UA. The visualization runs via the PLCnext Control and is web-based. This system is ideal for situations in which operators do not yet have their own control room.”

The smart control cabinet

What makes working with Phoenix Contact so special for Simon Züger? “We have a very similar mindset. Control cabinet building has a somewhat dusty image. Many companies and employees sit in their hamster wheel and manufacture and install system after system.

But we actually manufacture the heart of the electrical infrastructure and sit on an enormous mountain of data. But we haven’t done much with it so far. At Schibli, we think differently. We don’t just plan and implement control cabinets, we build electrical solutions.

Our mission is to make buildings and infrastructure smarter and safer. In the switchgear area, i.e. the automatic system, for example, through algorithms that detect changes in usage and thus trigger predictive maintenance of the system. Or recognizing user behaviour by analysing consumption and reporting deviations. This could be used in retirement homes, for example, so that an unusual deviation from the routine is reported and a caregiver is asked to look into the reason. As you can see: Completely new business models are waiting for us. Phoenix Contact’s vision of the intelligent control cabinet is therefore a perfect fit for us. And we look forward to continuing to develop and implement pioneering electrical engineering innovations for our customers together with Phoenix.”