When the only compressed air energy storage and gas turbine power station in Europe went into operation in Huntorf, Germany, in 1978, an energy revolution towards renewables had not even been thought of. But today, this unique technology could become an important building block for the All Electric Society.

During off-peak periods at night, the base-load electricity generated by large power plants should be stored and delivered during the day, at peak load times. This was the task of the compressed air storage power plant Huntorf, built in 1978. In addition, the compressed air storage facility should supply neighboring power plants with emergency power in the event of power grid failures, since these too require start-up assistance in such situations. Today, completely new tasks await the oldtimer of power stations.

Pressure down below

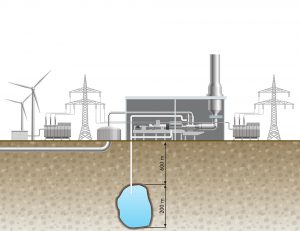

Compressed air energy storage sounds a little mundane. A little like compressed air cylinders. Pressure vessels of manageable dimensions. Those used in diving or as an air pressure dispenser at the gas station. But the scale on which the power station operators in Huntorf think has nothing to do with these small things. “To create these caverns, two salt domes were leached – that is to say, flushed out – from a depth of 650 to 800 meters,” explains Philip Eiben. It’s no wonder that the State Office for Mining, Energy, and Geology (LBEG) of Lower Saxony is responsible for the official supervision of the salt caverns.

And that holds up? After all, air is compressed up to 72 bar here. “There is still at least 600 meters of earth and rock between us and the caverns,” Eiben reassures us. The electronics technician for industrial engineering knows “his” plant inside out; after all, he has been working on it for seven years to ensure its smooth operation. “This storage technology has been tried and tested for decades. Next door there are deposits of natural gas, also in salt dome caverns. They are absolutely tight.” Eiben points to a plant that can be seen in the distance. “We receive our natural gas, which we need for energy production, from there.”

Gigantic air pump

Worldwide, there is only one comparable power plant in active use, and an experimental power plant in the Gotthard Base Tunnel. The principle of the pressure accumulator is very simple: If you have energy left over, it is used to drive a huge compressor, a kind of oversized air pump. This pumps air into the hollowed out salt dome. Up to 23,000 tons of air find room in the dark cave in the belly of the earth. If energy is now needed, this compressed air is allowed to rise again in a controlled manner to drive a gas turbine.

Because the air is humid and cools down as it expands, it would cause any system to freeze up. Natural gas is therefore supplied via a gas pipeline. This air-gas mixture is fed into a gas turbine and burned. Electrical energy is produced by a coupled generator. The proportion of natural gas in the air-gas mixture is around just three percent.

The efficiency, at more than 42 percent, is high compared to conventional gas turbines due to the natural gas and compressed air supply needed. “The balance will be even better if wind farms would otherwise have to be shut down because you don’t know what to do with the energy generated,” Eiben explains, convinced of the importance of his power station.

Black-start capable

The power plant can deliver the full capacity of 321 megawatts for three hours. For a further five hours, the plant will then operate at decreasing capacity in line with the falling compressed air pressure. This output is called up by remote control from the Düsseldorf control center by Uniper, the power plant operator. This is where dispatchers are located who permanently keep an eye on the electricity market and call up the energy from Huntorf when conditions are favorable.

This is also the economic task of the energy storage power station. This is because Huntorf can only be operated profitably if the electricity is sold at times when prices are high and stored when generation prices are low.

Currently, the energy storage facility is on standby for most of the year. A huge advantage of the energy storage power station is that it can be started very quickly. Within just three minutes, Huntorf is up and running at 50 percent, reaching full output after just seven minutes. And the system is “black-start capable”; that is to say, it can start up autonomously in the event of a total power failure and ensure that grid operations are restored.

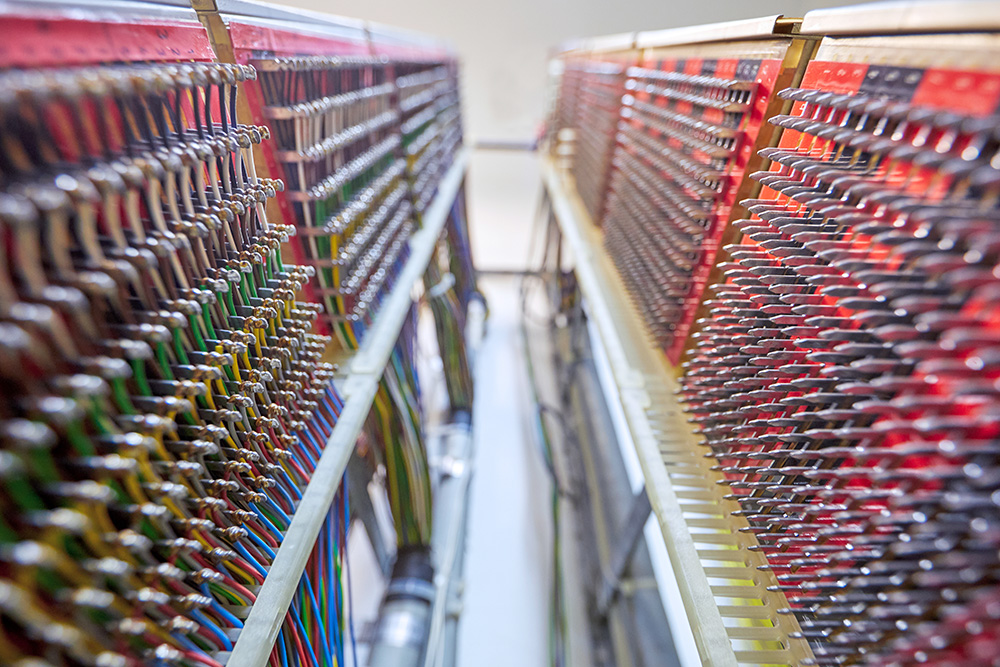

Starship Enterprise

The control system and the technical equipment installed here are as old as the power station itself – the control room is like a throwback to Starship Enterprise. Despite regular maintenance, it was clear that the equipment would not be able to meet future challenges.

One reason is that as part of the plant’s initial expansion, key operating data has to be read from the existing power station controller via the Modbus/TCP fieldbus protocol and displayed via web-based visualization. To ensure that the operating personnel can respond quickly to any malfunctions, relevant alert messages are sent to their smartphones. Furthermore, all operating data must be made available to the higher-level supervisory control room located at the Uniper power station in Wilhelmshaven.

The requirements of the operator make it clear that compatibility between the new technical system and the existing control engineering is crucial. At the same time, the solution should support future technologies. This is why, when it came to implementing the plant expansion project, Uniper chose PLCnext Technology from Phoenix Contact.

Protection for critical infrastructure

PLCnext Control is a component part of this ecosystem. It is an open control platform based on a Linux operating system. In the Huntorf power station, the PLCnext Control device reads the key operating data from the existing power station controller and forwards it to the local web visualization, which can be accessed using a standard browser.

Power stations are part of the critical infrastructure. They therefore require special protection when it comes to IT security so that attackers do not have an easy time. A fully and deeply integrated security strategy is the basis for comprehensive protection. To ensure the integrity, availability, and above all confidentiality of all data, PLCnext Technology offers security by design. The hardware and software are therefore already developed to be as robust and impervious to cyber attacks as possible.

“The PLCnext Control device is the ideal solution for connecting the Huntorf storage power station to the existing control system as well as for reading and forwarding the data,” reports Uwe Krüger, Head of Operations Power Plant Group Wilhelmshaven. “The open control platform enables us to flexibly combine the older existing communication paths with new solutions. This allows us to expand the power station without a great deal of effort and expense, ensuring that it is fit to handle future challenges.”