Until now, wind turbines have been considered a rock-solid affair. Anchored unshakably in the ground, the tower, the movable nacelle and the three rotor blades defy the forces of wind and weather. Until now. Because Sönke Siegfriedsen wants to unleash them from this earth-bound state.

The man is a true pioneer in the wind power industry. A successful entrepreneur. A technician. And a visionary and globetrotter. Second home China – not only for someone with headquarters in Rendsburg a big leap. With his Nezzy2 Sönke Siegfriedsen even leaves the solid ground. Because he and his team teach the wind turbine how to swim.

Floater is the name of this floating energy provider in the industry. And they enjoy a high level of attention. Because floaters could become an important element of global energy production. This is due to the limits that are poured into the concrete feet of the stationary plants. Namely, the need to balance the forces that pull on the entire plant 200 meters above it by means of a solid foundation.

The seabed must not be deeper than about 60 meters, because beyond that the massive concrete foundations cannot be laid in the seabed.

The solution lies in the chain

Sönke Siegfriedsen is a North German lad straight out of a storybook. Already comfortable on a sailboat by the age of three, he learned to sail at seven, and competed at age 14 in the Optimist dinghy world championships. Since studying physics in Lübeck, he has been addicted to energy and its production. And since visiting a pioneering wind turbine in Denmark in 1978, he has been aware that wind will not only have an affect in his sailing world.

He built his first wind turbine on the roof of the University of Applied Sciences in Lübeck in 1979. Since then, 50 patent families and 27 complete wind turbine generators have grown out of these early beginnings. “Over 50,000 turbines are in operation in China based on our design, our development,” says the head of aerodyn engineering gmbh proudly.

And he points casually over his shoulder with his thumb. “And this is our latest escapade.” We are sitting on the shore of a quarry lake between Cuxhaven and Bremerhaven in Germany. The sun is shining and the clouds are playing merry-go-round in the sky. A double-headed monster floats on the mirror-smooth lake, stretching a total of six rotor blades up to 18 meters in height. If its inventor has his way, the solution for the offshore wind industry is floating right here.

Stable thanks to tension

“The system weighs around six tons,” says Siegfriedsen, describing the dimensions of the floating wind turbine generator. Concrete weights are installed on the seabed to hold the hull of the wind turbine generator – a submersible buoy – in place using six anchor chains. This buoy is the floating foundation of the wind turbine generator. It is made up of pre-stressed, precast concrete elements, which come together in a horizontal Y shape. This floating foundation aligns itself autonomously using the wind current. In contrast to systems on land, it is not the single nacelles that rotate, but rather the entire above-water system.

The two towers, which are set up at an angle and connected to each other and to the foundation by anchoring cables, are built on this foundation. At the moment, three-bladed rotors are turning, but alternative two-bladed rotors are already waiting to be tested. The system is completed by large yellow floats, which are intended to ensure the stable floating position of the wind turbine on the water surface.

Testing – that is the motto. Nezzy2 is a research facility. A data collector. More than four million data are collected in 10 minutes. Every 10 minutes. Timo Kosnieczki, Key Account Manager of the wind team at Phoenix Contact, explains: “We were already involved in the predecessor Nezzy 1, which was tested in the Sea of Japan”.

Safely through the cyclone

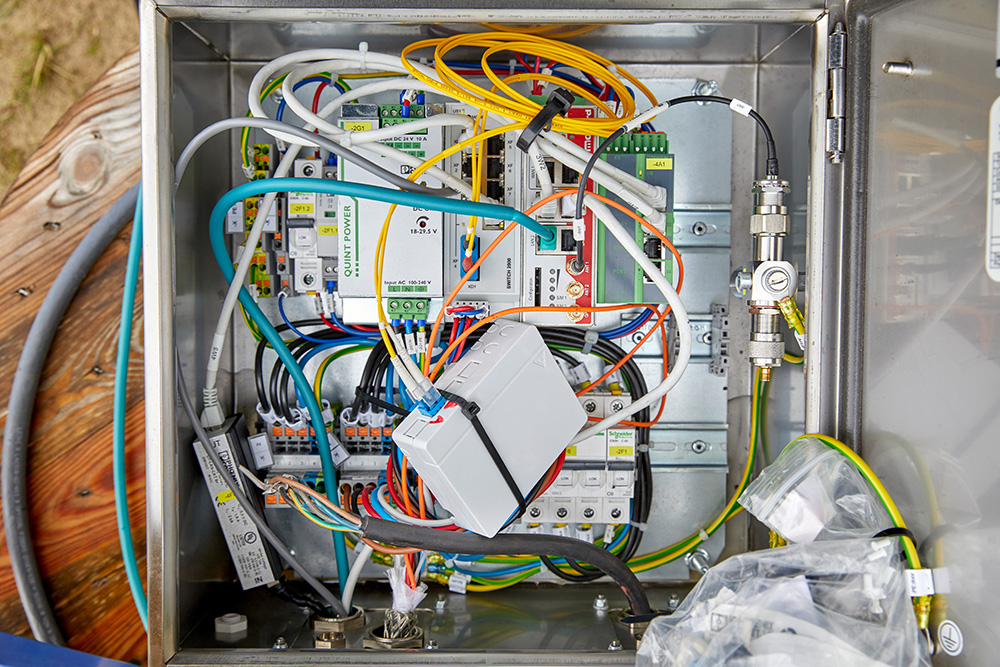

The double-headed system is stable thanks to its innovative clamping technology. Monitoring during operation is also very important. What happens if a rotor fails? Or high waves set the anchor chains in motion or a hurricane sweeps over the plant? Real-time data, high degree of automation, extreme reliability – without cutting-edge technology, Nezzy becomes a monster. With Nezzy2, the PLCnext Engineer program was already used during the development phase. From the pitch systems to the main switch cabinet, a total of six PLCnext controllers are used in the system. They record the sensor data, perform calculations and take over the correct control of the components. The control and synchronicity of the two turbines is of course extremely important.

No wonder that the colleagues of the wind team from Phoenix Contact are also fascinated. “For us it was the first time that we worked on and with a two-turbine system. That is very exciting. In order to add new functions and optimize the tasks of our automation technology, we exchanged new software packages with the colleagues from Recase almost every day,” says Application Engineer Lukas Christ, describing the pioneering work. Recase is the company that planned and commissioned the electrical engineering of Nezzy2. Timo Kosnieczky is visibly impressed by the double-headed monster: “This is truly pioneering work. And we are partners in real basic research. We are actively developing the programming of the control system in cooperation with Recase”.

And will all of this really hold together, even away from the quiet North German quarry lake and in dimensions ten times greater? “Of course,” Sönke Siegfriedsen says with certainty. “The system of floating work platforms is not new; the oil production industry has been using this concept for a long time. And wind turbines have also been taught how to swim. But the special thing about our system here is the concept of the two towers. This is the only way to ensure that the additional design work will pay off. Quite simply, the system can simply capture twice as much wind power.”

The real wind and waves will start to blow in October, when Nezzy2 is scheduled to move. Out of the lake, into the Greifswalder Bodden, into the Baltic Sea, which will then already be windy. How will the floating double head perform in current, strong wind and waves? If all the tests are successful, the whole world will be waiting for Nezzy – the construction of a real large-scale plant is to take place on China’s coast. Then the sensational wind turbine will stretch its two hubs into the wind at a height of 180 meters instead of 18. But in China you have experience with kites. So Nezzy2 can come quietly.

Aerodyn Energiesysteme

Recase Regenerative Energien

Phoenix Contact Windenergie

Addition

Sometimes reality overtakes you. Just a moment ago we were sitting on the shore of a dredging lake in Bremerhaven, Lower Saxony, interviewing wind energy pioneer Sönke Siegfriedsen, and his unique power plant presented here is already swimming in the Baltic Sea.

The 18 meter high wind turbine on a scale of 1:10 has meanwhile moved from the dredging lake to the Greifswald Bodden, off the German Baltic coast. Here it is exposed to the harsh reality of wind and waves. However, electricity is not yet being generated in this test phase, the builders and their partners around the energy provider EnBW reveal.