Speed is their motivation, deception their métier and water their means of transport – when these Swiss tinkerers get into the game, it gets wet, fast and almost certainly breathtaking.

Klarer Water Slides are a second-generation family business in Hallau, a town in German-speaking Switzerland. They are dedicated to acceleration in its wettest form, as they make water slides. If you’re thinking of the little kids’ slide at the local outdoor pool now, though, you’re wrong. “Fake Slide,” “Infinity Jump” or “Kamikaze” suggest that slides are thought of in a different dimension here. The products from Hallau are brightly colored, as high as a house, and the attraction in fun and adventure pools worldwide.

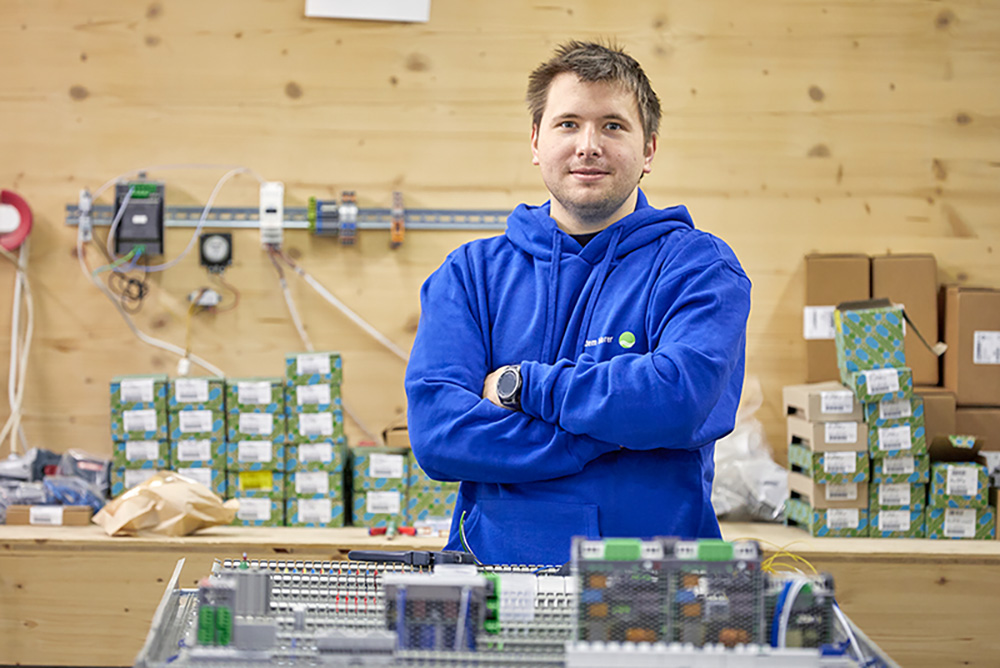

But the visit to the company headquarters is initially surprising. “We haven’t manufactured the slides here for a long time,” Tobias Beukelmann tells us and leads us into a surprisingly small production hall. There is no sign of bathing fun and rushing water currents, so the swimming trunks remain in the hand luggage. “This is where our slides are planned and the electrical engineering for them is manufactured. The elements are manufactured in Slovakia. The necessary metalworking shop is also located there.”

Beginning with sledge runs

The development manager of E-Technology explains: “The company was founded by Armin Klarer more than 30 years ago. He started out with toboggan runs made of GRP. These had to be made smooth after production. And that was done with a lot of water, rags and, of course, slides. So it was only natural that at some point, instead of padded winter pants, he decided to have fun in swimwear. In the meantime, the business is run by Claudia and Stefan Klarer, the next generation. And with the second generation it became international. Initially, we also manufactured the equipment here, but that changed years ago.”

So no swimming fun at work? Tobias Beukelmann grins: “Well, we can’t use water at all during the production and assembly of our control cabinets. But during the development of the air slide, for example, we set up the first test elements here on the lawn.” Aha, so a workplace with swimming trunks next to a respirator mask and safety shoes after all! Beukelmann dampens the enthusiasm: “Well, the water is ice cold, so we don’t heat it up.

Slipped, asked, hired

Even though we are already close to the border with Germany in the north of Switzerland, the lack of dialect of our interlocutor is striking. “I come from Wuppertal and have only been employed here since 2016.” How does a Wuppertal native end up in Switzerland? “In Plettenberg there is a swimming pool with a large slide. And there, as a mechanical engineer, I was just curious who built it.” The question turned into a contact, and the contact turned into the job as head of e-manufacturing.

“The ideas for the various elements that make up our slides are born here in the team. For example, the Free Falls, where optical illusions make you think you’re sliding straight ahead until suddenly a ledge opens up underneath you. Or the High Fly, where the swimmer can master a jump. Standing Slide, Looping, Magic Tube and brand new Stormchaser, where we work with a turbine that can even shoot the bather uphill with wind speeds of up to 100 km/h.”

Each of the approximately 40 slide systems that are created each year is a custom-made product, adapted to the wishes and conditions of the operators on site. “My team and I manufacture the necessary control cabinets here in Hallau. Timing, effect controls, lighting and music as well as videos and touchpoints in the installations are planned and controlled by us, along with the connection of the sensor technology in the installation. Only the water technology is not in our hands, that is realized by the operator. And we then also put the slides into operation on site.”

Acceptance by TÜV

Up to 120 m3 of water rushes down the smooth lanes per hour. “We get a signal from the pump as to whether operation is okay, then we control the system right down to the access controls, for example in the form of turnstiles. Of course, every installation is safety-checked and approved by TÜV Süd.”

In production and at the control cabinet, it is clear that Klarer Wasserrutschen has a close connection to East Westphalia. “In addition to terminal blocks from the ST line, we also use switches and relays from Phoenix Contact. M-Guards guarantee us the safety of the electrical systems.” In addition to tools from Blomberg, the Swiss also use Phoenix Contact’s labeling technology. “The installations have to be reliable, even if the end customer is just having fun in the bathroom. But the operator can’t use malfunctions at all, so the need for smooth, safe processes and simple maintenance routines is the same as in industry.”

Because if the slide stops, the fun stops. But Tobias Beukelmann and his small team are pretty sure that they won’t get wet on the next breathtaking attractions.

Klarer Freizeitanlagen AG

Phoenix Contact MGuards