Fast, safe and with unique functions – the brand new KNX power supply has what it takes to become the darling of the trade and the secret star of the control cabinet – whether in private homes or commercial buildings.

Good weather, a good mood, a great construction site in a prime location. But for Phoenix Contact employees, this is a rather rare professional environment: we are in a new development area above the small town of Bad Driburg in East Westphalia. Here we meet with Peter Töws and Nico Lehn from the company Elektro Rulle. The two master craftsmen are in the process of connecting up a smart new building. The green KNX strips can still be seen everywhere. As we follow Peter Töws around the construction site, he explains: “Our company offers the full bandwidth of electrical engineering. That’s why KNX is a recurring theme for us, which we use in private buildings like this one, but also in commercial buildings. This ranges from office and seminar buildings to clinics and church buildings.”

A KNX system consists of sensors and actuators. Sensors are field devices that are distributed decentrally throughout the building and record information about the environment, such as temperature, light intensity or movement. Actuators are usually central devices that are installed on the mounting rail in the distributor and react to the information collected by the sensors and perform actions such as switching on lights or opening blinds.

Communication between sensors and actuators takes place via the KNX network. The standard is frugal, the data finds its way either via twisted pair cable (KNX TP), powerline networks (KNX PL), Ethernet (KNX IP) or completely wirelessly via radio (KNX RF).

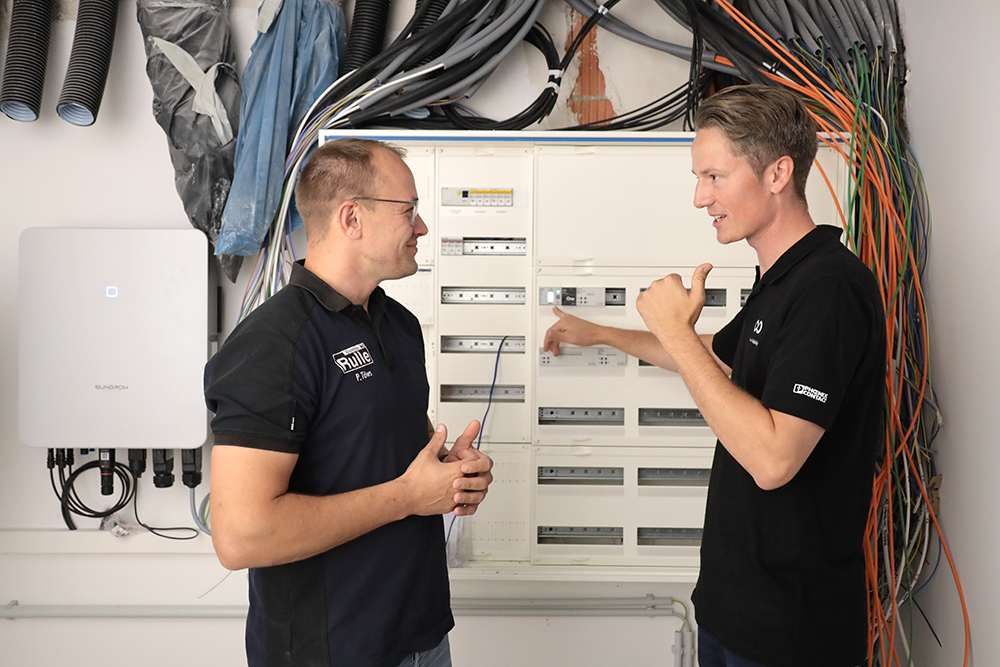

We stand in front of the control cabinets in the future utility room. Arm-thick cable harnesses, bundles of conduits – a familiar working environment for our two master electricians. And Daniel Diekmann, Product Manager at Phoenix Contact and also a trained electrician, is also in his element. In contrast, the small color display that has found its place here is unusual. Expert Diekmann explains:

“The biggest cost factor with KNX is the devices themselves. On the other hand, the effort involved in laying them is immensely reduced. Once the star-shaped cable harness has been laid, the further wiring of the actuators to be connected and their programming into the system is quick, flexible and uncomplicated.” Peter Töws adds with a glance at the cable harnesses: “If you use conventional wiring, especially in new buildings, then you are fixed to the function and location of the units. This can only be changed with a great deal of effort. A light switch then remains in the place where it was planned. Even if it turns out later that it is not actually useful there in everyday life. The additional gain in flexibility and ease of use provided by KNX recoups 100 percent of the costs. Today, electronics in building technology are attracting much more attention due to the many new functionalities that are becoming increasingly popular.”

With complex systems comes the challenge of maintaining an overview. The 41-year-old Töws, now General Manager at Elektro Rulle, explains why the new KNX power supply is so valuable to him: “We know the Catalog for building installations from Phoenix Contact almost by heart and rely on the components from Blomberg wherever it makes sense. The new Step Power for KNX is a great success. Because as soon as it is connected, we immediately have a comprehensive overview of the entire system. The power supply ensures that all components of the KNX system function properly and communicate with each other. The voltage is used for communication, with the voltage being short-circuited for a minimum amount of time. The KNX devices are operated via the current.

As uncomplicated as the system is during operation – if there is an error, the search for it can take a lot of time. We’ve already had situations where we’ve spent half a day measuring our way through a KNX installation. With the new power supply, we don’t have to do that, because the display tells us the status of the system immediately and we can start troubleshooting. Regardless of all the other product features, this has not been available on the market before. It would have saved us hours of searching.”

Daniel Diekmann adds: “You can even use the KNX power supply like a mobile diagnostic instrument. As soon as you apply the voltage, you can immediately see what’s going on in the system.”

Peter Töws is satisfied with the newcomer in the control cabinet: “With the new power supply, we not only have a reliable helper in the KNX environment. The client himself can also see immediately that we have created real and innovative added value for his new home. This also creates additional trust in our trade.” He speaks and, together with young master craftsman Niko Lehn, turns back to the cable harnesses that are still waiting to be wired.