Lithium is the gold of the 21st century. The modern world demands its use on a massive scale, for example in large-volume batteries. How nice it would be if the crumbly metal could be extracted from domestic deposits. And in an environmentally compatible way, too. Can that really be true?

To clarify this question, we made an appointment on site. In Karlsruhe. With both feet, so to speak, above the Upper Rhine Graben, which runs through here. And with someone who should know. Professor Jochen Kolb conducts research on this topic at the Karlsruhe Institute of Technology (KIT). The experienced geoscientist and mineralogist knows exactly what is true about the report that the gold of e-mobility comes out of the ground in this region virtually by itself.

The white gold

Lithium does not occur in nature in pure form; the alkali metal is far too reactive for that. As pure lithium oxide, it looks like crumbly cream cheese. But this reactive light metal is in great demand because it gives mobile energy sources, i.e. rechargeable batteries, a long and robust life that can be recharged again and again. The problem is that it currently comes mainly from Australia or Chile and does not necessarily enjoy the most environmentally friendly reputation due to its extraction methods.

Depending on the type, batteries require about 80 to 130 grams of chemically pure lithium per kilowatt hour of stored energy. About 10 kilograms of the rare metal are installed in a Tesla Model S. There are still far too few batteries that are recycled, as the power sources for e-cars simply last too long. Therefore, lithium must be extracted from either rock (Australia) or brine (Chile). Or …

The treasure under the Upper Rhine

… it bubbles up at you. Because there are places in the shell of Mother Earth where thermally heated deep water not only releases energy, but also carries dissolved lithium and plenty of other coveted substances. Exactly this situation prevails in the Upper Rhine Graben. Even the ancient Romans knew how to make themselves comfortable here thanks to thermal baths.

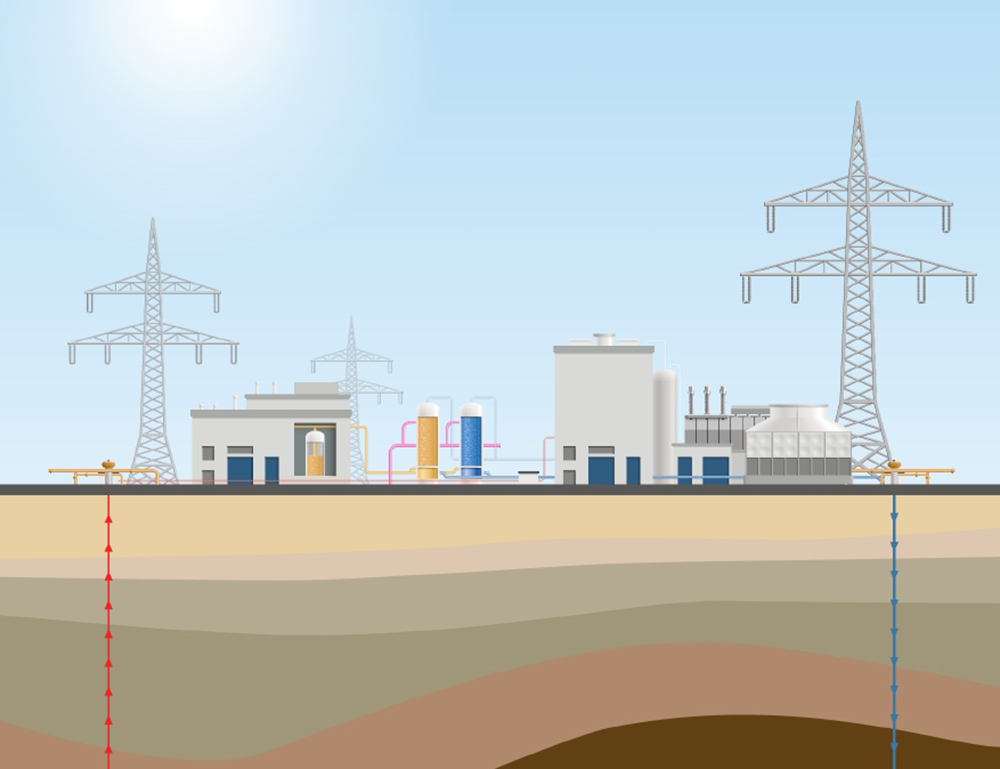

These days, there’s less of a call for a warm foot bath. Instead, the focus is on tapping deep layers of rock for geothermal power plants. In Bruchsal, the boreholes reach down to a depth of 2,500 meters, in neighboring Alsace a good twice as deep. There are geothermal power plants in Bruchsal, Landau, Insheim and in Soultz-sous-Soultz, Rittershoffen and La Wantzenau on the French side.

The 160-degree hot water from the depths is tapped by means of two boreholes. In the first borehole, the hot water is pumped upwards and injected back down through a second borehole at a pressure of up to 50 bar. Ideally, this is an almost closed circuit, because the hot water releases its energy through a system of heat exchangers. This is either fed directly into a district heating network or used to drive turbines that generate electricity. “However, this only makes sense if the temperatures are very high, such as in Iceland,” says Jochen Kolb.

Conveying with filters

Kolb and his team are at their best when it comes to the hot water from the depths. The hot brine contains a considerable concentration of lithium. Enough to produce about 20,000 batteries each year from just one well for Tesla, for example. That makes interested parties sit up and take notice: Together with EnBW, there is the Unlimited project, which is financed by the BMWi and runs for four years.

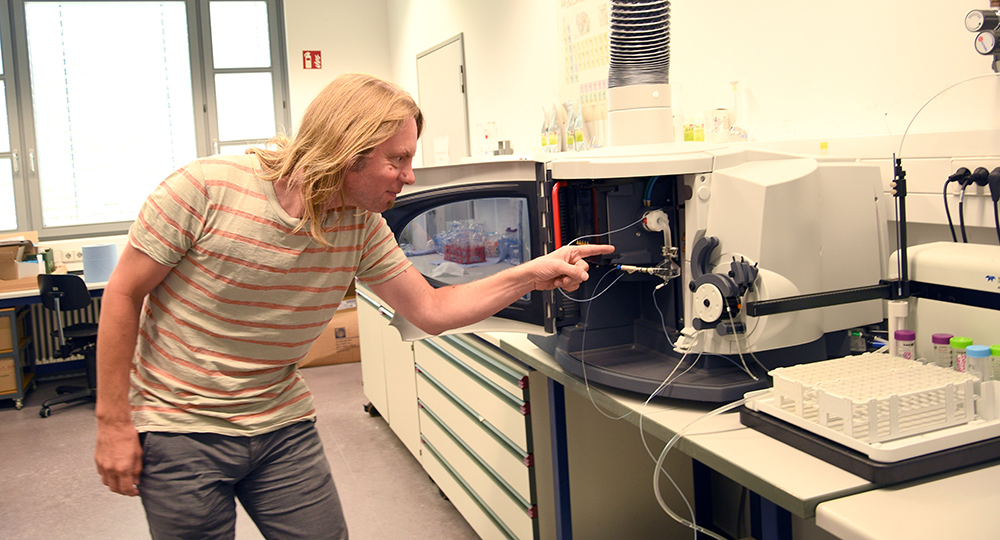

Professor Kolb is an expert on deposits. Before taking up his professorship in Karlsruhe in October 2016, he spent ten years working on raw materials geology in Greenland. In Karlsruhe, around 40 people work in his team and conduct research on topics related to the extraction of gold, copper, cobalt, rare earths or even lithium. “We are an applied branch of science. We develop models that industry can use to search for and extract raw materials.” In neighboring Bruchsal, Kolb and his colleagues are on the trail of lithium in thermal water.

But how do you get the raw material of the energy transition? Using a bypass system, the geologists want to tap into the circuit of the thermal power plant in Bruchsal. Here, around 30 liters per second flow from the depths through the plant. The water is very salty, carrying about 150 grams of dissolved substances per liter, about four and a half times more particles than in seawater, for example. Of these, about 160 milligrams are lithium. That is much less than in the salinaries of the Andes, where up to 1,000 milligrams are present. But the high flow rates in the plants, ranging from 30 to 70 liters per second, make extraction interesting.

Raw material from the bypass

Initially, only a small portion of this is to be diverted and then run through the pilot plant. Lithium and other raw materials from the naturally heated solution are chemically and mechanically filtered out here by means of a manganese oxide, then the brine flows back into the system and is pumped back to depth. The manganese oxide is freed from its lithium load and recovered. The recovered lithium chloride can then be used in precipitation reactions to produce either lithium carbonate or lithium hydroxide for battery production.

What worked in the laboratory in a test tube as part of a master’s thesis must work in a flow-through in the pilot plant. That’s also the big challenge: “The system is installed downstream of the heat exchanger, but works with water that is still 60 to 80 degrees hot and large amounts of unwanted solutes.

For Bruchsal, we expect lithium extraction that should be enough to produce a battery in an e-bike every two minutes and a Tesla battery every 40 minutes or so. However, we cannot yet estimate the size of the deposit. We don’t know the conditions underground well enough yet that we know when salt reduction will dilute the deep water and give us less yield. However, we assume that the deposit will be recoverable for at least 20 years,” says Professor Kolb optimistically.

Profit and loss

Geothermal energy is usually an additional business in places where there is no volcano heating the earth’s crust to the soles of your shoes. “Here in Bruchsal, it only works with subsidies, because the heat exchange and thus the heat output is still too low. The power plant in Rittershofen, France, however, is used to dry crops for a starch factory. In Munich, an increasingly large part of the district heating network is currently being supplied by deep geothermal energy. It’s working out excellently there.”

But it gets really interesting when the “white gold of electromobility” falls off as a by-product, so to speak. And with minimal impact on the environment. “If you do it right, even the risk of earthquakes is safely manageable.” Combine the heat generation with the lithium yields from the geothermal plants, and the economic scenario changes drastically.

This does not always have only positive consequences. The scientifically motivated gold miner knows all about the hunger for rare metals: “The demand for them is a bit like a gold rush. A lot of small companies are rushing into it, which are sometimes on the edge of respectability, where the stock market meets the marketing spectacle. That can work, but it can also be a pure air act.”

So no representative of the automotive industry has yet to set off for Karlsruhe: “In EnBW, we have found a partner who will work with us to build this first pilot plant, which is scheduled to go into operation in 2023. If it works, then it will be up to the industry to get larger plants up and running. I expect that such a large-scale plant will then require another five to ten years of development.” Anyone who is now impatient with the opportunities that the fire of the earth holds in store in terms of renewable energies and new raw materials: For geologists, who otherwise calculate in millions of years, this period is a piece of cake!