Can the world still be saved? CO2 emissions are still rising worldwide. What if we not only avoided climate-damaging carbon dioxide, but reclaimed it from the atmosphere? Crazy idea? A Swiss company shows how it can be done.

Meeting place: waste incineration plant. Or waste incineration, as it is called in Swiss official language. It’s cold, a gusty wind whistles through pipelines, around chimneys and through the lattice tube steps that have brought us to the roof of the imposing industrial plant. We are in Hinwil, in the Zurich Oberland. In the distance, we can glimpse the Swiss mountain panorama, for autumn is well advanced even in the land of the Confederates. Garbage is being burned beneath our feet, but on the roof of the Kehrichtverwertung, the air is fresh and clear.

We breathe “waste

Which brings us to the gaseous object of our desire. Air. We not only use the earth to deposit millions of tons of waste on and in it. Not only the oceans, which have to absorb the legacies of our civilizations. Since the beginning of the Industrial Revolution, we have also been using the gaseous body of our planet to absorb the volatile remains of our hunger for raw materials. Every year, we pollute the atmosphere with more than 34 billion tons of carbon dioxide, and the trend continues unabated.

The atmosphere of our Earth has formed over millions of years. Thanks to the evolutionary invention of photosynthesis, single-celled organisms and green plants on a large scale have fished carbon dioxide out of the air and, in combination with the energy of sunlight, converted it into more complex carbon compounds and thus into biomass. The waste product was and is oxygen. When plants decompose again, they theoretically release exactly the same amount of carbon dioxide that they previously bound. Fortunately for us, not all plants decompose. Often humus is formed, which, layered on top of each other, gradually becomes more impermeable to oxygen. This slows down decomposition, and the carbon dioxide remains stored in biomass. And is thus removed from the atmosphere. We ourselves can make good use of the excess oxygen that this produces, for example for our own respiration.

The principle worked brilliantly until man came up with the idea of using the stored biomass on a large scale as a source of energy. Peat, coal, crude oil and natural gas are all remnants of the plant surplus that has been accumulating for millions of years. By using these materials, we are releasing the bound carbon dioxide. The consequences have long been known: Greenhouse gas effects and a climate change that will have catastrophic consequences, at least for all oxygen breathers on this planet.

Solution approaches

Saving

The obvious thing to do now would be to drastically reduce CO2 emissions. After all, this emission threatens all of our existence in its current form. But CO2 emissions will increase worldwide in the next few years, to well over 40 billion tons.

The problem is the human psyche. It is true that we are well prepared to cope with sudden crises, to manage disasters and to survive accidents. But climate change is gradual to begin with. The effects barely affect the global regions in particular, which are responsible for the majority of emissions. So decision-makers often prefer short-term profit to the long-term survival of future generations or distant regions.

Although the economy is now redirecting in many segments, the speed at which this is happening will hardly be sufficient to avoid crucial tipping points at which climate events change drastically.

Removal

But what if you didn’t just focus on fossil fuel conservation? What if you actively “take” the CO2 back out of the atmosphere? And use it to be able to operate in a climate-neutral way? Or store it in such a way that it would be removed from the material cycle? This is precisely the idea that Christoph Gebald and Jan Wurzbacher had. The two German-born mechanical engineers met at the beginning of their studies at ETH Zurich in 2003, and the result of this meeting and their subsequent joint work is what we are looking at in Hinwil.

The technology

The approach of the two mechanical engineers should delight any technology enthusiast. After all, they rely on innovation to remove man-made excess CO2 from the atmosphere. During our visit to the roof of the waste recycling plant, we are accompanied by members of the PR team of Climeworks, the former start-up founded by Gebald and Wurzbacher in 2009 as an ETH spin-off. In the meantime, the exciting start-up has long since become an exciting company with an international flair. “The interest in our plant is enormous; we are now here at least twice a week and take visitors up to the roof.” This makes this waste incinerator probably the most visited plant of its kind in the world.

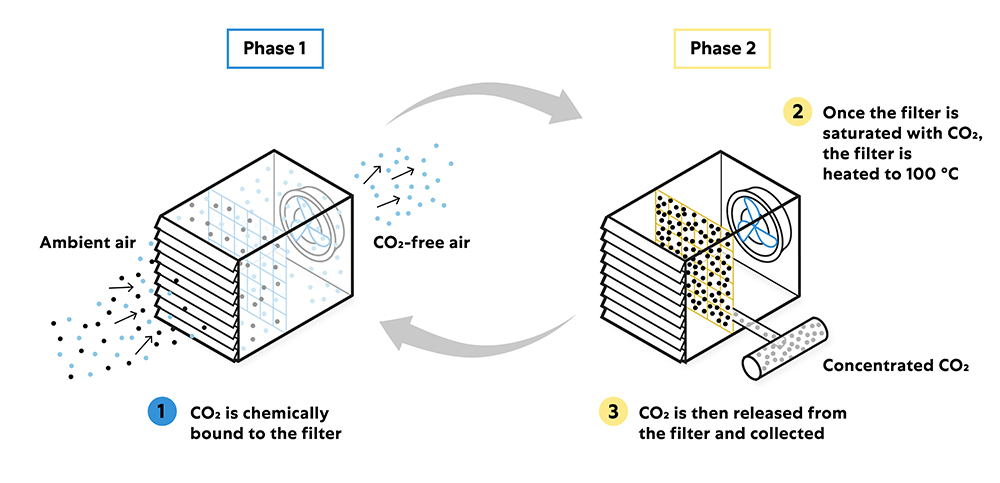

The Climeworks colleagues point to one of the house-sized structures that have found their place on the roof. Modular in design, the individual elements consist of large fans that draw in air and push it through a filter system. “The technology is called direct air capture. We suck in air and send it through a filter material, removing carbon dioxide. This is similar to a sponge that absorbs CO2 molecules. The air that escapes the plant is significantly lower in CO2 than before.”

When the filter material is saturated, the respective suction port closes automatically. At temperatures of up to 100 degrees and under vacuum, the carbon dioxide is separated from the filter material and the filter is ready for use again. The carbon dioxide is collected, cooled and compressed. How the separation works and the exact composition of the filter material is hidden from the view of curious competitors or media representatives, because it takes place inside the large containers that are part of the Climeworks plant. Therefore, we are also denied a view of the inner workings, including its control elements. Around 1,500 tons of CO2 are extracted here in Hinwil every year.

Location advantage heat

“The location of the plant is not for cleaning the exhaust air generated by waste incineration,” we are told when asked. “Rather, we need the thermal energy generated here to release the CO2 from the filter.” Climeworks has thus skillfully eliminated a weak point in the Direct Air Capture technology: For the separation of CO2 and filter material, the high energy input is otherwise a real and very expensive penalty. The separation of carbon dioxide alone accounts for around 80 percent of the total energy requirement.

There are several companies around the world that have built similar plants. But the Hinwil plant is the only one so far that commercially fishes CO2 out of the atmosphere and – now comes the second part in terms of climate optimization – also makes it usable. “Here in Hinwil, we use the extracted CO2 in two ways.” First, a local vegetable farmer uses the gas as fertilizer for his plants. Within sight is a greenhouse complex: “With the CO2 surplus, the growth of tomatoes, cucumbers or eggplants is improved, because for the plants carbon dioxide is a basis of their photosynthesis and acts like a fertilizer.”

And one local beverage producer uses the CO2 to produce its carbonated mineral water. The water refiners collect the extracted gas and use it in their production. It is also conceivable to fill completely different tanks, as carbon dioxide is a basic component of synthetic fuels. If the energy for refining is obtained from renewable sources, such fuels would even be nearly CO2-neutral. Therefore, it is not surprising that Audi has been a Climeworks partner since 2013.

CO2 sink in Iceland

While in Hinwil, Switzerland, the captured CO2 is reused and thus released back into the air, a Climeworks plant has gone into operation on Iceland that aims to permanently rob atmospheric dirt of its gaseous form and put it underground. “Orca” is the name of the latest and sensational plant from the Swiss filter pioneers.

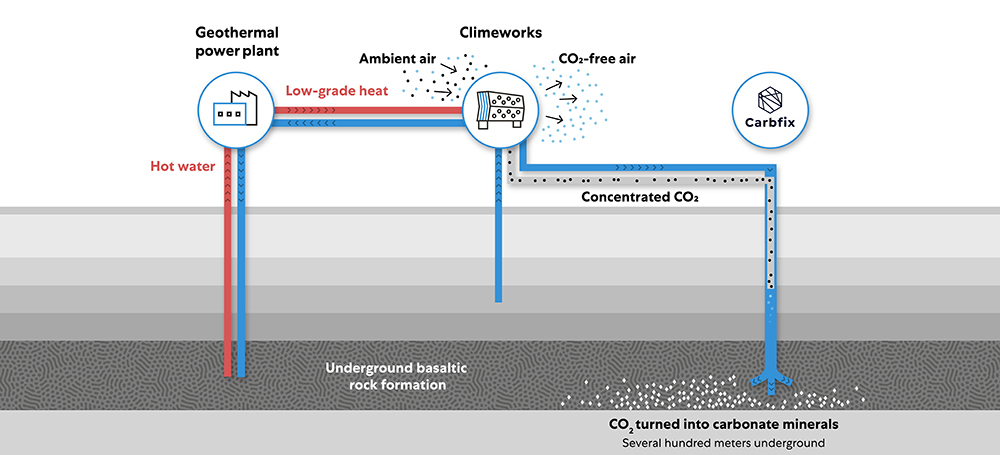

Here, the filtered CO2 is bound in water and then pressed up to 600 meters deep underground. It accumulates in the mineral-rich rock layers there – it virtually petrifies. “With the Orca plant, we can show that we can scale our technology as required,” explain the experts at Climeworks. “We can filter more than four times as much CO2 in Iceland as here in Hinwil.” But why Iceland of all places? “There we encounter optimal factors. By means of a nearby geothermal power plant, we get the necessary energy for our technology completely regeneratively. And injecting the carbon dioxide is also easier here because the situation of the underground is known. Besides, the global atmosphere doesn’t care at all where you extract the gaseous carbon dioxide.”

The partner in the planned burial of carbon dioxide is the Icelandic company Carbfix, which has developed the technology for the final storage of CO2. To be sure, the amounts removed from the atmosphere are still tiny when compared to annual global emissions. But as Direct Air Capture is rolled out, the contribution the technology can make will become more critical.

Bold visions

The plans of the 150-employee company are very ambitious: “Our vision is to inspire one billion people to remove CO2 from the air,” says co-founder Christoph Gebald in an interview. Climeworks has now built 15 plants worldwide, and the trend is rising sharply.

However, if the excess CO2 emitted each year (about ten gigatons) were to be recaptured solely through plants like the one in Hinwil, it would take about eleven million of the nation’s CO2 fishers. So we still can’t get around reducing carbon dioxide emissions globally.