Next to financial independence, vertical integration is one of the cornerstones of Phoenix Contact’s corporate philosophy. Our own screws marked the beginning. The small fasteners are still being produced by the millions. And non-stop 24/7…

Everything is dark and cold. The Phoenix Contact factory premises in Blomberg are largely in the dark. The offices are deserted, the parking lots empty. Yet, the lights are still on in some of the halls. It’s the night shift. The colleagues from production and manufacturing now have the campus to themselves. Hall 2 – Screw manufacturing is at home here in Blomberg. You encounter the heat as soon as you stick your nose through the doors. Plus the smell of cutting oil, hot metal, and hard work.

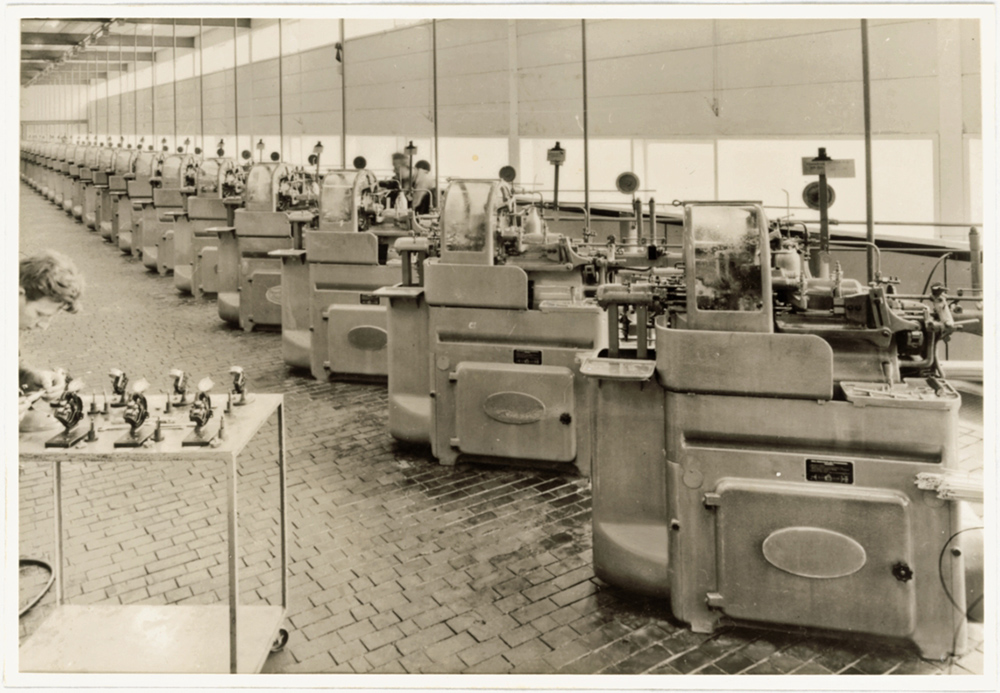

Production hall with history

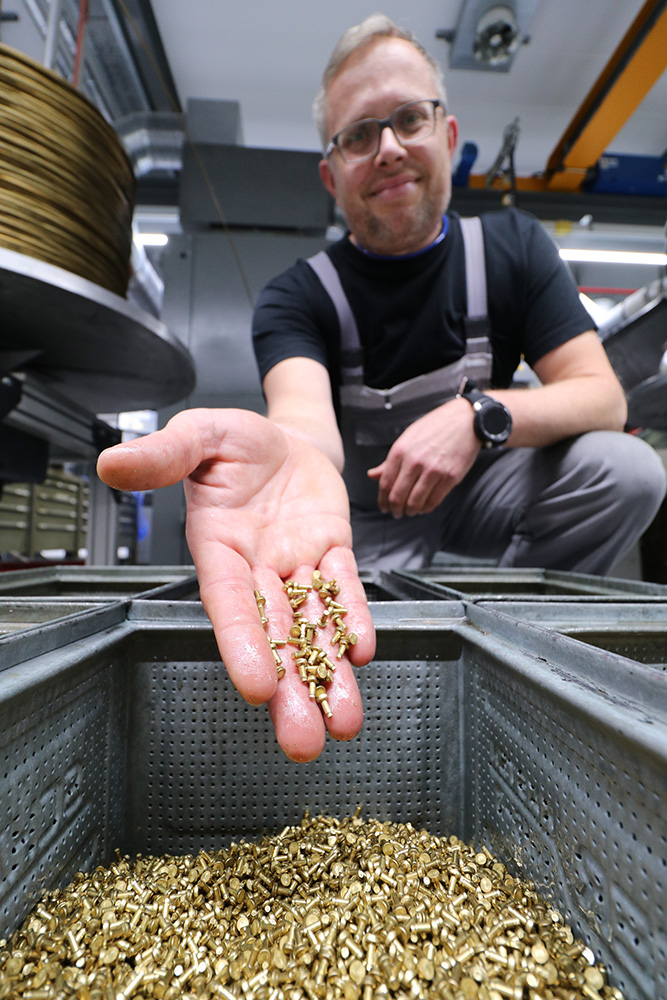

Falk Wiehager associates this with pleasant smells and normal working hours. The likeable machine operator has been employed with Phoenix Contact since 2005 and has worked in screw manufacturing for the past 16 years. Not a unique case, because for most of the 40 employees in screw manufacturing, Hall 2 has been their second home for many years.

It all started with a big problem. No sooner had Josef Eisert taken over management of the company than the company experienced delivery bottlenecks with the manufacturer supplying the screws at the time. Company management, which was still based in Essen at the time, was informed that a promised and urgently needed quantity of screws for terminal assembly could not be delivered, because the supplier preferred large orders.

Josef Eisert took this as the impetus he needed to set up his own screw manufacturing, which he accomplished in record time. For the former trading company, this marked the turning point towards becoming a manufacturer of its own products. For the Blomberg location, this marked the decision to establish production facilities on the Flachsmarktstrasse.

Snipping screws

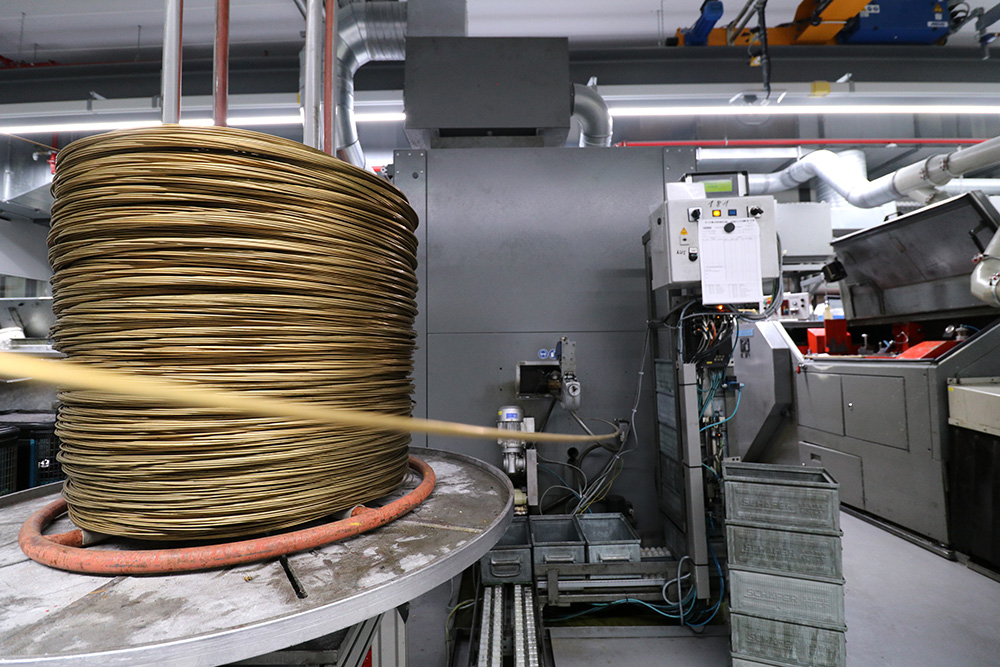

Today’s Hall 2 was already in 1957. However, you would not know this based on the industrial building’s outer appearance, nor on the production inside. There are newer machines on one side of the hall, where the raw material comes in as wire coils and leaves the other end as screws. On the other side, we find a classic screw production, where each of the processing steps are still open.

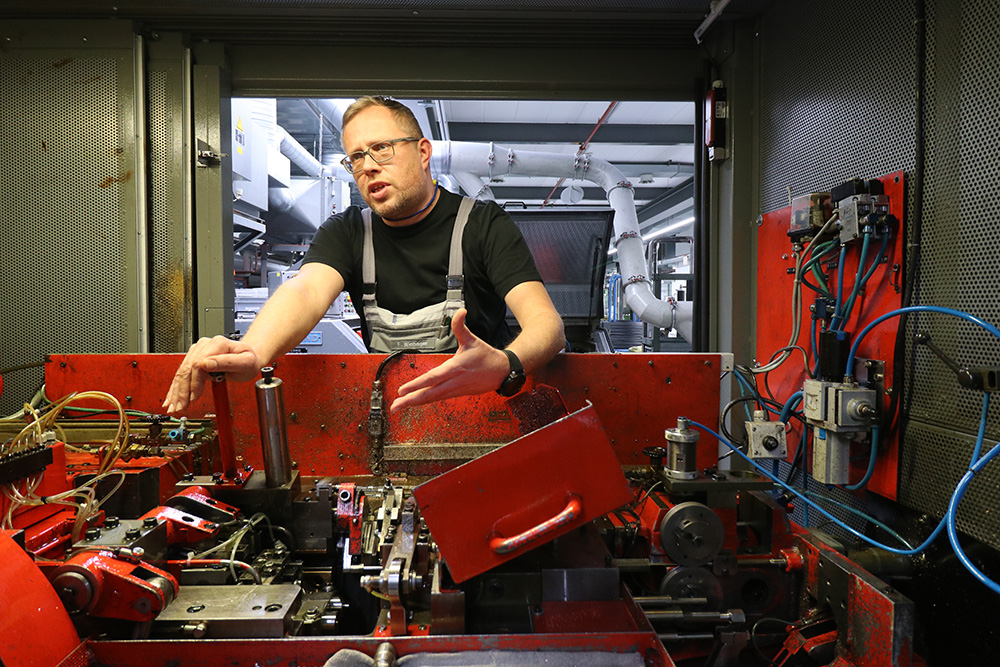

Falk Wiehager explains how “his” screws are made: “We process a range of different materials, from stainless steel. The wire comes on a roll, which is called a coil. The coil is placed on a reel, a kind of stand, and then, supported by a motor, releases the wire to the feeder, which then pulls the material into the machine. There, a blade cuts pieces off the stand with always the same length. This blank is then moved in front of the die. A so-called prediver moves forward, pushing the blank into the die, and then the finish-diver arrives, giving the screw its final shape.”

In the screw universe

The finished product comes in very different shapes, depending on the order. Right now, we produce 207 different types of screws at Phoenix Contact. Whichever machine is available always has to be set up and adjusted accordingly. The machine setter is responsible for setting the machine up, and the machine operator for running the machine. The specific technical knowledge cannot be learned at a school desk. “I’m actually a trained IT technician and starting here was more or less a coincidence. The task is versatile, though, and really technically demanding. After all, the machines have to be set precisely to a hundredth of a millimeter and then have to run.”

Wiehager doesn’t mind working rotating shifts – whether the early, late, or night shift. On the contrary: “This gives me time for my hobbies, and for the kids as well.” The interpersonal aspect is the most important thing for the specialist from East Westphalia: “We’re a great team here. The work can sometimes be very stressful, yet we are a really close-knit community here. If the team is right, then any job is fun.”

The billion product

The 47-year-old takes pride in the performance: “Depending on the order volume, we produce up to seven million screws a day here. And do so with the highest precision. In a year, we reach a volume of around 1.6 billion screws.” Wiehager and his colleagues receive recognition for their efforts by regular visits from Klaus Eisert and others: “He must have come in here 15 times during his evening rounds over the last ten years. The number of his visits has of course become less. The senior executive is not getting any younger. But we here are close to his heart. After all, he helped set up the screw manufacturing.”

How does he view himself and his team? “We are really important workers in our production.” He says, grins, and turns his attention back to inspecting the screws. There are still a few of the small fasteners to be made before reaching the daily seven million mark.